-

×

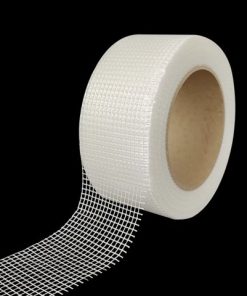

Dryvit Grid Tape 4" x 300': Construction Tape

1 × $36.00

Dryvit Grid Tape 4" x 300': Construction Tape

1 × $36.00

Dryvit E Finishes: Dirt Pickup Resistance Lightweight Finish

Features:

- Lightweight

- Greater elasticity

- DPR and PMR chemistry

- Vapor permeable

- Multiple deliveries

- Cleans with water

Benefits:

- More square footage per man per day

- Increased crack-bridging ability

- Resistant to dirt and the growth of mold and mildew

- Will not trap moisture vapor

- May be trowelled or sprayed

- Less time and labor for clean up

Safety

Dryvit E Finishes: Dirt Pickup Resistance Lightweight Finish

Dryvit E Finishes, Quarzputz E, Sandpebble E and Sandpebble Fine E finishes are lightweight, premixed 100% acrylic-based coatings, which are offered in standard colors as well as custom colors in Dryvit’s Pastel and Mid-base formulations. Packaged in pails weighing nearly half the weight of standard finishes, the E finishes allow for far greater ease of application at the same coverage rates and the same high performance as all Dryvit finishes. Dryvit E Finishes are more flexible than standard acrylic finishes. Questions? Contact Us.

E finishes are durable and provide surface color and texture for Dryvit systems. These finishes can also be applied over other properly prepared substrates such as exterior masonry, stucco, precast or cast-in-place concrete. The finishes are also suitable for interior applications. All finishes can be trowel applied or spray applied with a hopper gun or pole gun-type sprayer.

Drying Time: Drying of the finishes is dependent on the air temperature, relative humidity and coating thickness. Under average drying conditions [70 °F (21 °C), 55% R.H.], E finishes will dry in 24 hours. Lower temperature and higher humidity will require that the E finish be protected for longer periods. Protect work from rain during the drying period.

Testing Information: For individual test data on this product’s properties, refer to the chart included with this document.

Job Conditions: Air and surface temperature for application of E finishes must be 40 °F (4 °C) or higher and must remain so for a minimum of 24 hours.

Temporary Protection: Shall be provided at all times until the E finish is dry, and installation of permanent flashings, sealants, etc. are completed to protect the wall from inclement weather and other sources of damage.

Some settling of the E finish may occur during shipping. Thoroughly mix the E finish with a ”Twister” paddle or equivalent mixing blade powered by a 1/2 in (12.7 mm) drill, 450-500 rpm, until a uniform workable consistency is attained. It should not be necessary to add water. If a looser workability is desired after mixing, add no more than 2 oz (59 ml) of water per pail of any E finish.