Dryvit Prymit: Primer/Adhesion Promoter

Features:

- Water-based primer

- Excellent adhesion

Benefits:

- Easy clean up

- Good initial grab

Dryvit Prymit: Primer/Adhesion Promoter

Prymit is a specially formulated 100% acrylic water-based primer, which ensures excellent adhesion and alkali resistance when bonding Dryvit Backstop NT or adhesively-attached EIF systems to latex and oil-based painted surfaces. Prymit also provides adhesion to glazed brick and tile. Questions? Contact Us.

Prymit can be used on properly prepared sound glazed brick or tile as well as previously painted masonry surfaces prior to the installation of Dryvit Backstop NT or adhesively-attached EIF systems, provided that the paint is sound and well bonded to the substrate.

Appearance: Slightly glossy film.

Drying Time: The drying time of Prymit depends on the porosity of the substrate, the air temperature and relative humidity. Under average drying conditions, [70 °F (21 °C), 55% R.H.], Prymit will dry in two hours. Protect from rain for at least 4 hours.

Job Conditions: Air and surface temperature for application of Prymit must be 40 °F (4 °C) or higher and remain so for a minimum of 24 hours.

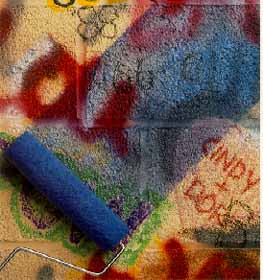

Testing for Adhesion: The performance of Prymit and the Dryvit adhesively-attached EIF system over previously painted masonry surfaces depends upon the soundness and the adhesion of the paint. To determine the suitability of the substrate, the following testing procedure is recommended.

1. Clean the surface with a mild detergent, rinse thoroughly and allow it to dry.

2. Apply a coat of Prymit to approximately 1 ft² (.093 m²) of the cleaned surface and allow to dry.

3. When specified, apply a coat of Backstop NT and allow to dry a minimum of 24 hours.

4. Prepare a small amount of Dryvit adhesive mixture following Dryvit’s recommendations. Apply the mixture to a 2 in (51 mm) thick block of expanded polystyrene (EPS) approximately 3 in x 3 in(76 mm x 76 mm) and press the coated block onto the Prymit coated surface.

5. Allow the adhesive mixture to cure for three (3) days.

6. Pull the EPS block off the substrate.

7. The substrate is acceptable only if the failure is within the EPS block. Otherwise, the surface is not satisfactory for application of Prymit; and an alternative method of installation must be used.

8. An adequate number of tests shall be conducted to ensure all project conditions are