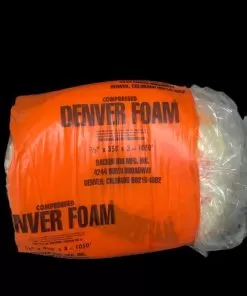

Mini Denver Foam 1-1/8 Bag: Open Cell Backer Rod 100′

$75.19

MINI BAGS NO LONGER SOLD. SEE FULL SIZE BAGS.

- For use in expansion/construction joints

- Concrete and pre-cast concrete walls,

- Floors

- Partitions

- Bridge construction

- Parking decks

- Curtain walls

- Glazing

- Log home construction

- Highway construction,

- Pavement maintenance

Out of stock

Mini Denver Foam 1-1/8 Bag: Open Cell Backer Rod 100′

Mini Denver Foam 1-1/8 has an advantage allowing air to reach both sides of sealant offering a faster and more uniform cure. This is especially true for one part non-sag sealants. Mini Denver Foam 1-1/8 can also be used in floor joints with self leveling sealants. Care should be taken in traffic areas where additional support is required. Questions? Contact us

Per ASTM C 1330 type O, DENVER FOAM is a non- gassing backer rod used as a backing for elastomeric and other applied caulking sealants. Denver Foam® controls the depth of the applied sealants and ensures cross- sectional hour-glass configuration.

Specific Uses: For use in expansion/construction joints in concrete and pre-cast concrete walls, floors, partitions, bridge construction, parking decks, curtain walls, glazing, log home construction, highway construction, and pavement maintenance.

Both hot and cold applied sealants can be used with DENVER FOAM per ASTM-D-5249-95

DENVER FOAM 1-1/8 is continuous lengths of flexible, round, fabricated open cell polyurethane foam; yellow or black in color and available in a wide range of diameters listed in section 8 under packaging information.

DENVER FOAM is also manufactured in half round shapes referred to as DENVER FOAM HALF ROD. Most commonly used in log home chinking applications, its unique design compresses securely into the joint while providing a flat chinking surface eliminating rounded backer rod telegraphing.

DENVER FOAM HALF ROD can also be used in control joints with shallow depths where conventional round backer rod will not fit. Half Rod still allows for the proper sealant hour glass configuration and offers all of the advantages of traditional DENVER FOAM.

DENVER FOAM® is chemically inert and will resist oil, gasoline and most solvents. Material is odorless and will not stain. The open cell construction eliminates the out-gassing and cold flow problem associated with closed cell polyethylene backer rods.

DENVER FOAM® should be installed in construction joints free from all contaminants, loose materials, and dry and free from frost. Install under minimum 25%, maximum 80% compression to offer a good tooling base. Systems can be installed without the fear of out-gassing associated with polyethylene closed cell backer rods.

Unless otherwise agreed to in writing, DENVER FOAM is sold without warranty, express or implied. Buyer must make their own determination as to the suitability of the product and application.

| Weight | 13 lbs |

|---|

Related products

All Products

Backer Rod

All Products

All Products

Backer Rod