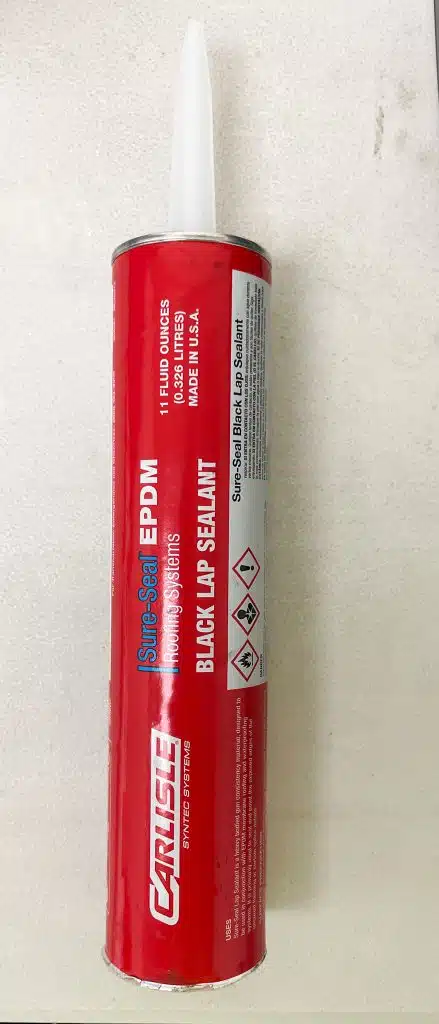

Carlisle Sure-Seal EPDM: Lap Sealant (11oz)

$13.80

Carlisle’s Sure-Seal Lap Sealant is a gun-consistency material used to

seal the exposed cut edge of reinforced EPDM membranes, and the edges

of elastoform flashing. Carlisle’s Lap Sealants are extremely durable, and

their cured rubber consistency enables them to expand and contract with

the roofing membrane. Sealant should be restored to room temperature prior to use

195 in stock

SKU: 255987

Categories: Carlisle, Carlisle, Carlisle Waterproofing, Cutting Tools/Hand Tools, EIFS & Adhesive, Sealer, Sealer/Waterproofing

Tags: CarlIsle, Sealant, Sure-Seal, Tube, Tube 10oz

Carlisle Sure-Seal EPDM Features and Benefits

- Seals exposed cut edge of reinforced EPDM membranes and the edges of elastoform flashing.

- Cured rubber consistency

- Applied using a caulk gun

- Seals EPDM edge splices

Coverage Rate

This material has a coverage rate of 22′ (6.7 m) per tube using a 5⁄16″

(8 mm) bead.

Installation

1. All surfaces to be sealed with Carlisle Sure-Seal EPDM Lap Sealant must be firm, dry, and free of oil, dust, and other foreign materials.

2. After splices are completed with the proper splicing materials, clean

the EPDM to remove all foreign materials by wiping with a Carlisle

HP Splice Wipe (or equivalent) dampened with Carlisle Weathered

Membrane Cleaner.

Note: Permeation resistant gloves (that meet ANSI/ISEA 105-2005) are recommended while using this material.

3. Apply a 5⁄16” (8 mm) bead of Lap Sealant along the exposed edge of

the membrane.

4. Using the feathering tool supplied with the Pressure-Sensitive

Elastoform Flashing, feather the sealant bead so the high point is

above the offset of the splice and the edges are feathered onto

the deck.

5. Lap Sealant must be applied and feathered on any required

elastoform flashing edges by the end of the working day. Lap sealant

may be applied immediately to the elastoform flashing.

Precautions

- Review the applicable Safety Data Sheet for complete safety information prior to use.

- Lap Sealants are FLAMMABLE. They contain petroleum distillates that are dangerous fire and explosion hazards when exposed to heat, flame or sparks. Store and use away from all sources of heat, flame or sparks. Do not smoke while applying. Do not use in confined or unventilated areas. Vapors are heavier than air and may travel along the ground to a distant ignition source and flash back. A red caution label is required for shipping.

- Avoid breathing vapors. Keep container closed when not in use. Use with adequate ventilation. If inhaled, remove to fresh air. If not breathing, perform artificial respiration. If breathing is difficult, give oxygen. Call a physician immediately.

- If swallowed, DO NOT INDUCE VOMITING. Call a physician immediately.

- Avoid contact with eyes. Safety glasses or goggles are recommended. If contact with eyes occurs, immediately flush eyes with plenty of water for at least 15 minutes. Contact a physician immediately.

- Avoid contact with skin. Wash hands thoroughly after handling. In case of contact with skin, thoroughly wash affected area with soap and water.

- Follow Carlisle’s recommended splice instructions. DO NOT USE as splice cement between membranes.

- Jobsite storage temperatures in excess of 90°F (32°C) will shorten product shelf life. Should the Carlisle Sure-Seal EPDM Lap Sealant be stored at temperatures below 60°F (15°C), restore to room temperature prior to use.

- By using an excessively wet solvent cloth while cleaning the splice edge, solvent may be left in the offset of the membrane sheets. To avoid this problem, use a damp rag and make sure the Weathered Membrane Cleaner is completely flashed off before Lap Sealant application.

- If applied during periods of cold, dampness or high humidity, it is possible that the evaporation of solvents will be substantially reduced, resulting in some slight membrane swelling. This would be further aggravated should the sealant be applied in an unusually heavy coat.

- Coverage rates are average and may vary due to jobsite conditions.

- KEEP OUT OF THE REACH OF CHILDREN

For more information contact us

| Weight | .75 lbs |

|---|---|

| Color | Black |

Related products

Cutting Tools

$33.40

All Products

$68.35

Carlisle Waterproofing

$275.31

All Products

$11.50

Air and Vapor Barrier

$238.80

Cutting Tools

$53.85

All Products

$209.30

Carlisle Waterproofing

$222.87