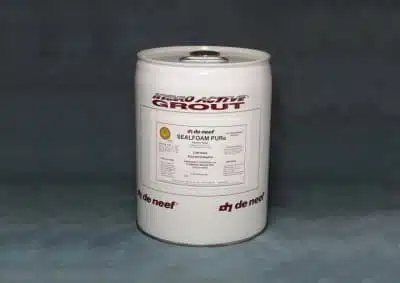

DENEEF Seal foam PURe 5 Gallon

$1,047.83

DENEEF Sealfoam PURe – Key Features:

- Single-component, easy-to-use polyurethane resin

- Expands up to 5 times its original volume

- High tensile strength and strong adhesion

- Resistant to chemicals, thermal movement, and wet/dry cycling

- Ideal for sealing both wet and dry non-structural cracks

- Solvent-free and eco-friendly formulation

5 in stock

DENEEF Seal foam PURe Detailed Overview

Product Description: DENEEF Seal foam PURe is a state-of-the-art, single-component polyurethane resin designed for the efficient sealing of non-structural cracks in various construction materials. It is hydrophilic, utilizing MDI (Methylene Diphenyl Diisocyanate) as its base, and is free from TDI (Toluene Diisocyanate) and solvents, ensuring safer application and minimal environmental impact. Upon curing, it transforms into a flexible, closed-cell foam with outstanding tensile strength and adhesive qualities, alongside commendable resistance to chemicals.

Key Features and Benefits:

- Eco-Friendly Composition: Free from TDI and solvents, reducing potential environmental and health hazards.

- High Expansion Capability: Expands up to five times its initial volume, effectively filling voids and cracks.

- Robust Physical Properties: Offers excellent tensile strength and adhesion, ensuring long-lasting repairs.

- Thermal and Hydrological Stability: Capable of withstanding thermal movement and cycles of wet and dry conditions.

- Single Component System: Simplifies the application process, as no mixing is required before use.

- Versatile Chemical Resistance: Provides durability against a range of environmental aggressors.

Applications: Ideal for sealing dry and wet moving non-structural cracks. Its expansive properties make DENEEF Seal Foam suitable for a variety of repair needs in concrete and other building materials, particularly where moisture presence is a factor.

Packaging & Handling:

- Available in 5-gallon metal pails, 50-gallon drums, and 10.5 oz cartridges.

- Sealed under dry nitrogen to prevent premature activation by moisture.

- Store in original containers at temperatures between 40°F and 90°F to maintain optimal usability.

- Utilize contents swiftly after opening to prevent wastage, owing to moisture sensitivity.

Installation and Usage:

- Preparation: Ensure substrates are clean and free from debris. Pre-test on a small scale before full-scale application.

- Application: Inject directly into cracks; the resin will expand to fill and seal. Adjust water ratios according to crack conditions (neat for wet cracks, 1:1 with water for dry cracks).

- Tool and Equipment Cleaning: Use DENEEF Washing Agent to clean tools before the resin cures.

Safety and Precautions:

- Adhere to safety guidelines by using protective gear such as gloves and goggles.

- Consult the SDS for comprehensive safety instructions.

- Emergency contact: CHEMTREC 1-800-424-9300 for immediate assistance.

Limitations:

- Sensitivity to temperature: Utilize heat bands if application conditions are cold to maintain product efficacy.

- Water Reactivity: Ensure no water enters open containers as the resin is water-activated.

- pH Levels: Use water within a pH range of 3-10 for activation to ensure optimal foam quality.

The DENEEF Seal foam PURe is an innovative solution tailored for effective crack sealing applications, providing a robust, environmentally considerate option for modern construction needs.

| Weight | 45 lbs |

|---|---|

| Dimensions | 15 × 15 × 18 in |

Related products

All Products

All Products

All Products

All Products

Concrete Repair

All Products

Concrete Repair

All Products