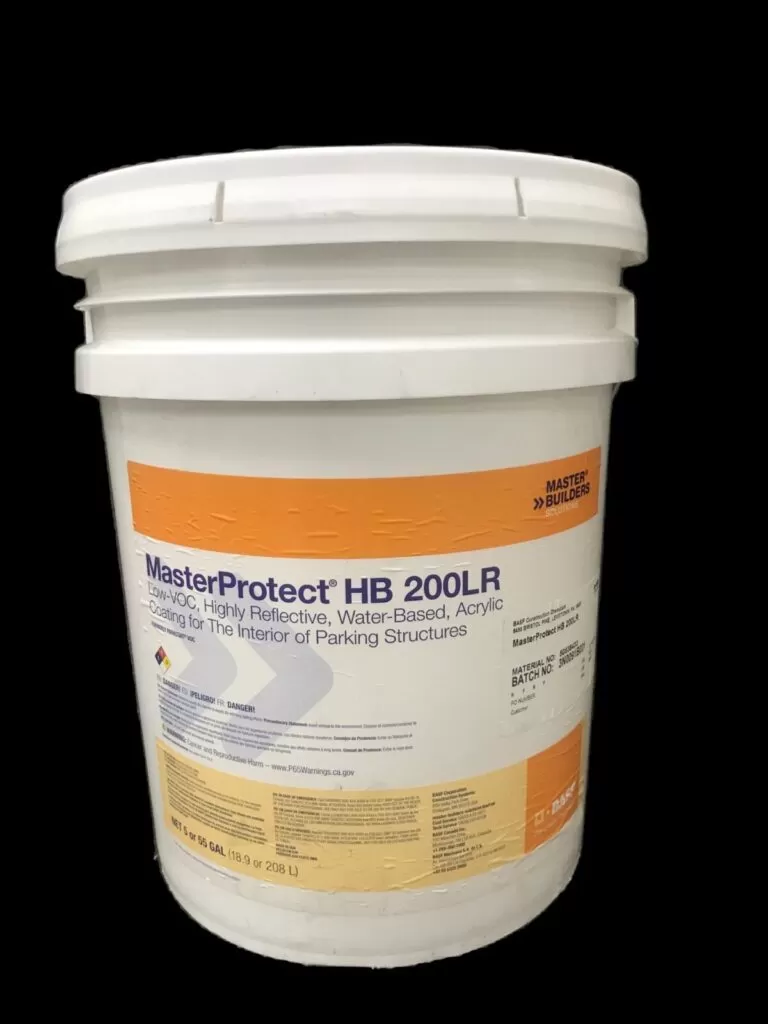

HB 200LR: Masterseal Reflective Coating

$287.62

• High light reflectivity enhances the security of garages and increases lighting efficiency

• Airless spray application speeds production and reduces turnaround time

• Excellent adhesion, bonds securely to substrate for long-term durability

• Excellent color retention; maintains brightness without fading over time

• Freeze/thaw resistant, suitable for cold climates

• Low VOC content for broad compliance across all regions

• Water based formula has low odor

• No dirt pick-up to maintain attractive appearance

• One-coat coverage lowers labor and material costs and returns structures to service quickly

• Effective carbon dioxide diffusion barrier, protects embedded steel from corrosion

4 in stock