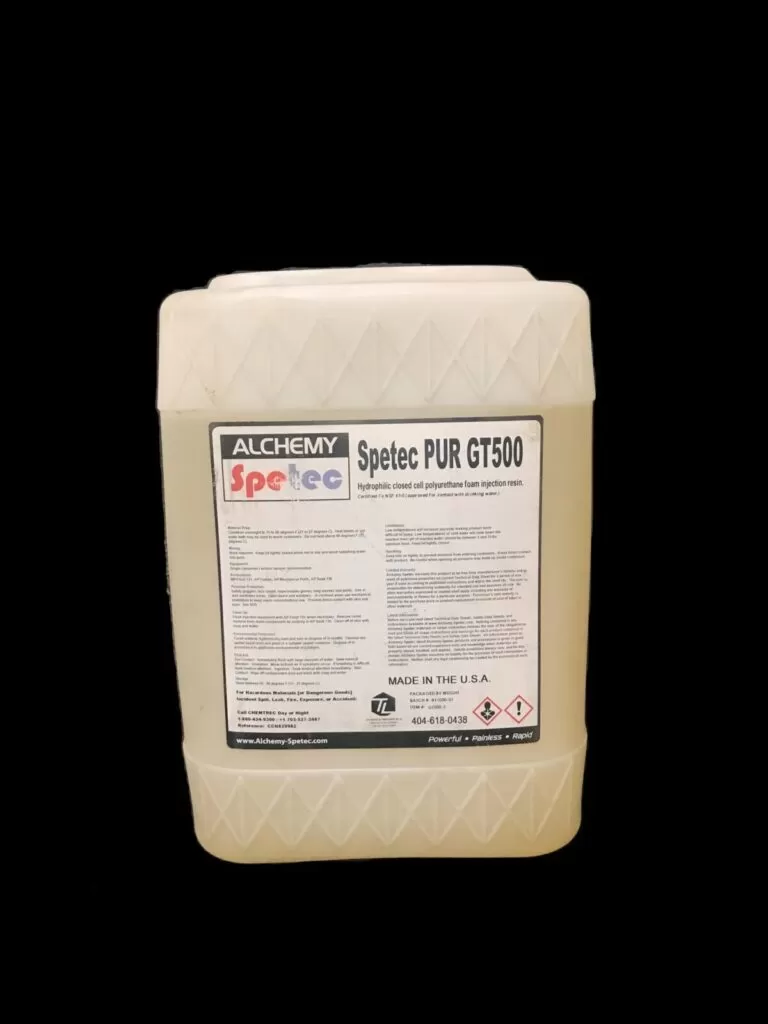

Spetec Pur GT500: Injection Resin 5 Gallon

$582.00

- Sealing cracks in concrete structures through pressure injection.

- Sealing hairline cracks, expansion joints, wide cracks, pipe joints, pipe penetrations.

- Saturating dry oakum to create a flexible gasket for sealing pipe penetrations, joints and larger defects in concrete structures.

- No catalyst required.

- Tenacious bond to wet concrete.

- High elongation.

- Thin enough to penetrate tight cracks.

- Moderately hydrophilic.

- Phthalate free (more environmentally friendly).

- Certified to NSF 61-5 (Approved for contact withdrinking water).

14 in stock

Spetec Pur GT500: Injection Resin 5 Gallon

SPETEC PUR GT500 is a single component, low viscosity, flexible hydrophilic polyurethane foam injection resin. Questions? Contact us

PRELIMINARY ANALYSIS

For leaking joints, identify if the cold joint runs vertically or horizontally. Injection holes have to be angle drilled into the joint. For leaking cracks, drill the injection holes in a zig-zag pattern around the crack to make sure that the injection hole intersects the crack.

PREPARATION OF THE SUBSTRATE

Drill at 45° angle into the crack or joint. Ideally the injection hole should intersect the joint or crack half way through the thickness of the wall or slab. Blow the dust out of the injection hole with a probe that reaches the back of the hole. Fix a packer of the right diameter into the injection hole.

PREPARATION OF THE PRODUCT

Read the technical and safety data sheets prior to commencement of the injection works.

PREPARATION OF THE EQUIPMENT

Depending on the application, injection can be carried out using a hand pump, pneumatic pump or electric pump. Use separate pumps for injection of water and polyurethane resin. Check that the pump is working properly. Prior to injection, the resin pump must be flushed with appropriate pump flush and be completely free of water to prevent pump blockage.

APPLICATION

- Start the injection at the first packer; for vertical joints or cracks this is usually the lowest packer.

- Do not over pressurize while injecting; the correct injection pressure is the pressure that allows to resin to flow into the crack or joint. Avoid injecting at pressures of more than 1500psi (100bar).

- If unreacted resin comes out of the joint or crack, stop the injection and move on to the next packer.

- After the last injection of resin into the packer, shoot a little bit of water into the packer in order to make sure that the last injected resin will react as well.

- Only catalyze the resin you will use within the next few hours.

- Always flush the pump out at the end of the day. Resin left in thepump overnight can damage the pump.REQUIRED TOOLSDrill and drill bits of appropriate diameter and length. Mechanical Packers of appropriate diameter and length. Injection pump; manual, pneumatic or electric.CLEANING AND MAINTENANCEAfter the injection, clean the pump with Spetec Pump Cleaner. If the pump will not be used for several days, flush the Spetec Pump Cleaner out of the pump with lightweight motor oil or hydraulic fluid and leave it there until the next usage. Never rinse the pump with water. After injection, remove the packers from the concrete and fill the holes with a fast setting cement or any other appropriate filler material.COMPLIMENTARY PRODUCTSFor certain application where a faster reaction time is needed a special fast catalyst can be used. Pump cleaner, Mechanical Packers, Oakum, and Injection Needles. SPETEC® I.T.S KIT or SPETEC® R-I.T.S SYSTEM must be ordered separately. See Technical Data Sheets.

Need more Spetec?

Spetec H100 Injection resin

- ADVICE / FOCAL POINTSAvoid injecting when temperatures are below -4°F (-20°C). In extreme cold conditions it is recommended to warm the resin and catalyst. Since SPETEC PUR GT500 is water-reactive, liquid water should be present.

| Weight | 50 lbs |

|---|---|

| Dimensions | 14 × 14 × 18 in |

Related products

All Products

All Products

All Products

All Products

All Products

All Products

All Products