Backer Rods, Blog

When to Use Backer Rod: A Comprehensive Guide

When to Use Backer Rod : A Comprehensive Guide for All

- Key Takeaways

- Deciding When to Use a Backer Rod

- Types of Backer Rods Explained

- Benefits of Incorporating Backer Rods

- Understanding Closed vs. Open Cell Rods

- Proper Application Techniques for Rods

- Enhancing Sealant Performance with Rods

- Selecting the Right Backer Rod

- Importance of Bond Breakers

- Summary

- Frequently Asked Questions

When should backer rod be used? We’ve got the answers. In this guide, we’ll dive into the ins and outs of backer rods, exploring their purpose, benefits, and ideal applications. Whether you’re a seasoned contractor or a DIY enthusiast, understanding when to use backer rods is crucial for ensuring a successful sealant project.

Key Takeaways

- Deciding when to use a backer rod is crucial for achieving effective sealant performance in various applications.

- Selecting the right type of backer rod, whether closed or open cell, is essential to ensure proper fit and sealant support.

- Incorporating backer rods offers benefits such as improved joint insulation, reduced sealant consumption, and enhanced sealant performance.

- Proper application techniques, including correct sizing, installation, and compatibility with sealants, are key to maximizing the effectiveness of backer rods.

- Enhancing sealant performance with backer rods involves understanding the importance of bond breakers and their role in preventing three-sided adhesion.

- Choosing the appropriate backer rod based on the specific project requirements and sealant type is crucial for achieving optimal results.

Deciding When to Use a Backer Rod

Assess Joint Width and Depth

When assessing whether to use a backer rod, we first measure the width and depth of the joint. If the joint is deeper than 1/2 inch, or if it has an irregular shape, we consider using a backer rod. This helps ensure proper sealant depth and adhesion.

Consider Sealant Type

Next, we take into account the type of sealant being used. For non-sag sealants or those with higher viscosity, we find that using backer rod provides crucial support for the sealant. It prevents excessive use of sealant material, and ensures better performance over time.

Evaluate Movement Capability

Finally, we evaluate the movement capability required in the joint. If there is substantial movement expected due to thermal expansion or building settlement, we definitely utilize a backer rod. This helps with joint movement and minimizes stress on the sealant.

Types of Backer Rods Explained

Closed Cell

We use closed cell backer rods in areas with high moisture content. These rods are impermeable, preventing the absorption of moisture. This makes them ideal for sealing joints in places prone to water exposure, like around windows and doors.

Open Cell

Open cell backer rods are highly compressible, making them suitable for irregular joint sealing. They easily conform to the shape of the joint, providing a tight seal. We find these beneficial for filling gaps around pipes and other uneven surfaces.

Benefits of Incorporating Backer Rods

Enhanced Sealant Elasticity

When using backer rods, we notice a significant improvement in the elasticity of sealants. The backer rod provides support to the sealant, allowing it to stretch and compress as needed without losing its original shape. This enhanced flexibility ensures that the sealant can effectively accommodate movements caused by temperature changes or structural shifts.

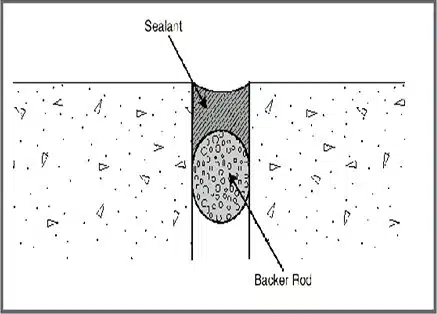

Controlled Sealant Depth

Incorporating backer rods allows us to control the depth of the sealant application more effectively. By placing the backer rod in the joint before applying the sealant, we ensure that the sealant adheres to the sides of the joint, maintaining a consistent depth throughout. This not only results in a neater finish but also prevents excessive use of sealant material.

Improved Bonding Strength

Understanding Closed vs. Open Cell Rods

Moisture Resistance

When it comes to closed rods and open rods, we must consider their cell structure, especially in terms of moisture resistance. Closed cell backer rods are highly resistant to moisture, making them ideal for applications where water ingress needs to be minimized. On the other hand, open cell backer rods have a more porous structure, allowing for some degree of moisture absorption.

Compatibility with Sealants

We’ve found that closed cell backer rods are particularly compatible with cold-applied sealants due to their low moisture absorption properties. This makes them suitable for areas where exposure to water and moisture is a concern. Conversely, open cell backer rods exhibit versatility with various hot-pour and cold-applied sealants, making them adaptable to different sealing applications.

Proper Application Techniques for Rods

Snug Fit

When it comes to applications of backer rods, we must ensure a snug fit by selecting the appropriate diameter for the joint. This ensures that the rod fits tightly within the joint, preventing any movement during sealant application.

Backer rods play a crucial role in providing support and maintaining the shape of the joint. By choosing the right diameter, we can effectively fill the void and create a solid foundation for the sealant.

Correct Depth

To optimize sealant performance, we insert backer rods at the correct depth. This ensures that the sealant adheres properly to both sides of the joint, minimizing air and moisture infiltration.

By placing the backer rod at an ideal depth, we facilitate proper adhesion of the sealant to the joint surfaces. This results in a durable and long-lasting seal that effectively prevents water penetration and air leakage.

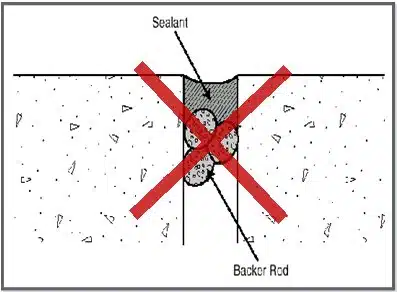

Bond-breaker Creation

One of the key specialty applications of backer rods is to create a bond-breaker for easy joint maintenance and refilling. The backer rod acts as a barrier between the sealant and the joint surfaces, preventing three-sided adhesion.

This technique simplifies future maintenance as it allows for easy removal and replacement of old sealant without damaging or adhering to the joint substrates. It also reduces material wastage during resealing processes.

Enhancing Sealant Performance with Rods

Reducing Caulk Consumption

When it comes to sealant materials, we’ve found that using backer rod can significantly reduce caulk consumption. By filling the gaps and voids with backer rods before applying sealant, we can control the sealant depth effectively. This not only ensures a more uniform application but also minimizes the amount of sealant required, ultimately saving us time and resources.

Improving Bonding

We’ve learned that utilizing backer rods is crucial for enhancing bonding in various applications. By inserting backer rods into joints or gaps, we can force the adhesive or sealant into closer contact with the surfaces being sealed. This creates a tighter bond and prevents air or moisture from penetrating the seal, ensuring long-term effectiveness.

Facilitating Joint Maintenance

In our experience with weatherproofing and construction projects, we’ve found that using backer rods can serve as an effective bond-breaker during joint maintenance. By placing backer rods in expansion joints or between different materials, we can facilitate easier cleaning and refilling processes. This helps prevent three-sided adhesion, allowing for proper movement accommodation and reducing the risk of joint failure over time.

Selecting the Right Backer Rod

FillPro™ Standard

When it comes to glazing installations, FillPro™ Standard Backer Rod is our top choice. Its purpose as a backing material adds support and maintains the required depth for sealants. The right flexibility ensures a snug fit, enhancing the overall performance.

We found that using FillPro™ Standard Backer Rod in window applications significantly improves the sealant’s effectiveness. It creates a solid foundation, preventing air and moisture infiltration. In pavement joints, this backer rod efficiently supports the sealant while allowing proper movement.

FillPro™ Hot Rod XL

For hot-pour sealants in concrete highways and driveways, we opt for FillPro™ Hot Rod XL Backer Rod. Its specific design caters to high-temperature applications, ensuring durability and longevity. This backup material effectively fills gaps and maintains the necessary shape for optimal sealing.

The use of FillPro™ Hot Rod XL Backer Rod has shown remarkable results in concrete highways. It provides excellent support to the sealant, enhancing its performance under extreme conditions. In driveway applications, this backer rod proves to be reliable in maintaining a secure seal against external elements.

FillPro™ Open Cell

When considering expansion joints, window glazing, and bridge construction, we consider FillPro™ Open Cell Backer Rod. Its unique composition allows for efficient airflow while providing adequate support to the sealant. This enhances the overall integrity of the structure.

In our experience with expansion joints, FillPro™ Open Cell Backer Rod has been instrumental in accommodating movement while effectively sealing gaps. In window glazing projects, this backer rod contributes to maintaining a secure outer skin, preventing any potential damage from external factors.

Importance of Bond Breakers

Creating a Barrier

When dealing with cracks and gaps, backer rods play a crucial role in creating a barrier. By inserting backer rods into the joints, we effectively establish a bond-breaker that prevents the sealant from adhering to the bottom, thus allowing for proper joint movement.

Facilitating Maintenance Processes

Utilizing backer rods as bond breakers is essential for facilitating maintenance processes. The presence of a backer rod ensures that when it comes time for joint cleaning and refilling, the process is streamlined. It allows for easy removal of old sealant without damaging the joint surfaces, making way for efficient resealing.

Enhancing Sealant Longevity

The use of backer rods to establish a bond-breaker significantly contributes to the longevity of sealant applications. By preventing three-sided adhesion, backer rods reduce the stress on the sealant, minimizing its exposure to solvents and environmental factors. This ultimately leads to a more durable and effective sealing solution.

Summary

We dove into the world of backer rods, exploring their various types, benefits, application techniques, and importance with sealant. Understanding when to use a backer rod is crucial for achieving effective sealant performance and enhancing the durability of construction projects. By selecting the right backer rod and comprehending the differences between closed and open-cell rods, we can optimize our sealant applications and ensure long-lasting results.

Incorporating backer rod into our construction practices not only improves the resilience of sealant joints, but also contributes to overall structural integrity. As we continue our journey in the construction industry, let’s remember the significance of utilizing backer rods and strive to implement these valuable tools in our future projects. Our commitment to excellence drives us to embrace best practices and enhance our construction endeavors for lasting success.

Frequently Asked Questions

When should backer rod be used?

Backer rod should be used to fill gaps and openings before applying sealant. They provide support to the sealant, improve its performance, and prevent three-sided adhesion. It’s essential for creating a proper seal in various construction and sealing applications.

What are the benefits of incorporating backer rods?

Incorporating backer rods enhances the overall performance of sealants by providing a proper shape factor, reduced consumption of sealant material, improved joint depth-to-width ratio, and minimized sealant wastage. It helps in reducing the stress on the sealant due to joint movement.

How do I select the right backer rod?

Selecting the right backer rod involves considering factors such as joint size, type of sealant, temperature variations, and application method. The appropriate backer rod should fit snugly in the joint without creating any bond at its bottom or sides while allowing proper sealant depth.

What are closed vs. open cell rods?

Closed-cell backer rod is a dense and non-absorbent, suitable for applications where moisture resistance is crucial. Open-cell backer rod is more flexible and compressible, ideal for accommodating joint movement. Understanding their differences is crucial for selecting the right type based on specific project requirements.

Why is it important to use bond breakers with backer rods?

Using backer rod prevents three-sided adhesion by ensuring that only two sides of the joint receive adhesion from the sealant. This helps maintain flexibility in the joint and prevents premature failure of the sealant due to excessive stress or strain on the joint.

Check out some of our Closed-Cell backer rod here!

Check out some of our Open-Cell backer rod here!