Blog

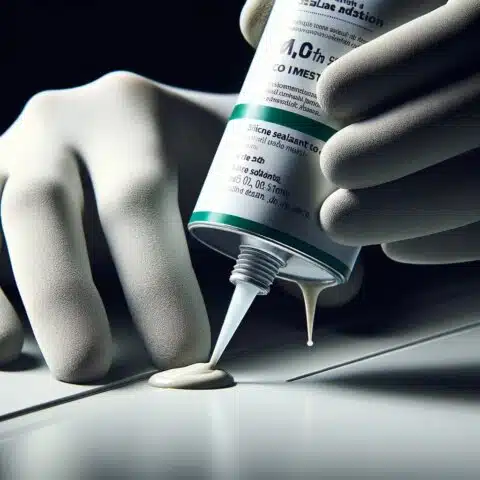

Will Silicone Sealant Stick to Silicone? Our Expert Tips

- Understanding Silicone Sealant Adhesion

- Will Silicone Sealant Stick to Silicone?

- Tips for Enhancing Silicone to Silicone Adhesion

- Preparing Surfaces for Silicone Sealant Application

- Effective Removal of Existing Silicone

- Overcoming Adhesion Issues with Caulk and Silicone

- Techniques for Ensuring Caulk Adheres to Silicone

- Addressing Damaged Silicone Surfaces with Sealant

- Closing Thoughts

- Frequently Asked Questions

Did you know that many people are surprised to find out that not all silicone sealants adhere well to silicone surfaces? It’s a common misconception, but the truth is, not all silicone sealants will stick effectively to other silicone materials. In this post, we’ll dive into the factors affecting the adhesion of silicone sealants to silicone surfaces and explore tips for ensuring a strong bond. Let’s uncover the secrets behind achieving reliable adhesion between different types of silicones.

Understanding Silicone Sealant Adhesion

Curing Process

Silicone sealants adhere through a process called curing. During curing, the silicone sealant transforms from a liquid to a solid state. This transformation creates a strong bond with the surfaces it is applied to. The curing process usually takes around 24 hours, during which time the sealant sets and adheres firmly.

Applying silicone sealant on clean, dry, and well-prepared surfaces significantly enhances its adhesion. We must ensure that the surface is free from dust, dirt, grease, or any other contaminants that may hinder adhesion. A simple wipe-down with rubbing alcohol can help remove any residual substances and improve the bonding of the silicone sealant.

Material Compatibility

The adhesion of silicone sealant depends on material compatibility as well. It’s crucial to use a high-quality silicone sealant designed for specific materials like glass, metal, plastic, or ceramic for optimal adhesion. For instance, if we’re sealing two pieces of glass together using silicone adhesive specifically formulated for glass surfaces will result in superior bonding compared to using a general-purpose one.

Understanding these factors is essential for successful application because they directly impact how well the silicone sealant sticks to various surfaces. By taking these into account and following proper application techniques like using primer when necessary or choosing an appropriate type of silicone based on material compatibility ensures reliable performance and longevity of our sealed surfaces.

Will Silicone Sealant Stick to Silicone?

Surface Cleanliness

Surface cleanliness is crucial. If the silicone surface isn’t clean, the sealant won’t adhere properly. We need to ensure that the silicone is free from dust, dirt, and any residue before applying the sealant. Cleaning with a suitable solvent or using rubbing alcohol can help achieve a clean surface for better adhesion.

Applying a primer specifically designed for silicone surfaces can also improve adhesion by promoting better bonding between the existing silicone and the new sealant. This step becomes important when dealing with old or weathered silicone surfaces.

Type of Silicone

The type of silicone being used also plays a significant role in determining how well the sealant will stick to it. There are different types of silicones available, such as acetoxy-cure and neutral-cure silicones. Acetoxy-cure silicones may not bond well with certain types of other silicones due to their acidic nature, while neutral-cure silicones are more versatile and compatible with various substrates including other types of silicones.

It’s essential to choose a neutral-cure silicone sealant if we want it to adhere effectively to an existing silicone surface without any compatibility issues.

Tips for Enhancing Silicone to Silicone Adhesion

Use Compatible Primer

Using a compatible primer is crucial. The primer creates a bonding surface for the silicone sealant, ensuring better adhesion between the surfaces. For instance, if we’re working on sealing a joint with silicone sealant, applying a specialized primer designed for use with silicone will significantly improve the bond. Applying the compatible primer helps prepare the surface and promotes strong adhesion between two silicone materials. This step is essential when working on projects that involve joining or sealing two silicone surfaces together.

Ensure Proper Surface Roughness

To further enhance adhesion between silicone surfaces, it’s important to ensure proper surface roughness. By creating micro-roughness on the surface, we increase the contact area available for bonding, thereby improving adhesion between two pieces of silicones. For example, lightly sanding or etching the surfaces can help achieve this desired level of roughness before applying the silicone sealant.

Creating an adequate amount of micro-roughness allows for better mechanical interlocking between the cured sealant and substrate, resulting in improved overall adhesion strength.

Select High-Quality Silicone Sealants

Selecting high-quality silicone sealants with strong bonding properties is paramount in achieving reliable adhesion between silicones. Opting for premium-grade products ensures that our applications benefit from superior adhesive capabilities and long-lasting performance. When choosing a suitable product, we should look for those specifically formulated to adhere well to various substrates including other silicones.

Preparing Surfaces for Silicone Sealant Application

Thorough Cleaning

Before applying silicone sealant to silicone, we always make sure to thoroughly clean and dry the surfaces. This is crucial as any dirt, dust, or moisture can hinder the adhesion of the silicone sealant. We use appropriate solvents to remove any contaminants from the surfaces, ensuring that there are no oils or residues left behind.

We take extra care when cleaning areas around windows and doors where silicone sealants are commonly used. Any water or moisture trapped between the surfaces can compromise the effectiveness of the sealant. By eliminating these impurities, we create an optimal environment for maximum adhesion.

Mechanical Abrasion

In some cases, especially when dealing with old silicone layers or non-porous surfaces, we resort to mechanical abrasion or sanding before applying new silicone sealant. This process promotes better adhesion by creating a slightly roughened surface that allows the new sealant to grip more effectively.

When preparing our bathroom for resealing around tubs and sinks, we ensure that all old silicone is removed completely before proceeding with cleaning and abrading the surfaces. This meticulous approach ensures that our new application of silicone adheres firmly without being hindered by residual old layers.

Effective Removal of Existing Silicone

Utilize Specialized Products

When applying new silicone sealant over existing silicone, it’s crucial to ensure that the old silicone is completely removed. To achieve this, we can utilize specialized silicone removers or solvents. These products are designed to efficiently break down and dissolve the existing silicone, making it easier to remove.

It’s important to note that using regular household cleaners may not be effective in removing silicone residue. Therefore, opting for dedicated silicone removers or solvents is essential for achieving a clean surface for reapplication.

Careful Removal Process

Once we have applied the specialized remover or solvent, we need to carefully scrape off the old silicone using suitable tools. This step requires precision and patience to avoid damaging the substrate underneath.

We should select tools specifically designed for removing silicone, such as plastic or rubber scrapers, which help prevent scratches on surfaces while effectively lifting off the old sealant. By taking our time and being meticulous during this process, we can ensure that the surface remains intact and ready for new application.

Thorough Cleaning

After successfully removing all traces of existing silicone, thorough cleaning of the area is vital before applying new sealant. We must use appropriate cleaners to eliminate any remaining residue from both the surface and surrounding areas.

This ensures proper adhesion of the new silicone sealant, preventing any potential issues caused by debris or leftover remnants from previous applications.

Overcoming Adhesion Issues with Caulk and Silicone

Choosing Compatible Caulks

Choosing the right caulk is crucial. Opt for caulks explicitly designed for use with silicone. These specialized caulks are formulated to adhere effectively to existing silicone surfaces, reducing the risk of adhesion issues. By selecting compatible products, we can overcome potential compatibility problems and achieve a strong bond between layers of silicone.

For instance:

- Look for caulks labeled as “silicone-compatible” or “adheres to silicone” on their packaging.

- Seek recommendations from hardware store professionals regarding the best caulk options specifically tailored for use with silicone.

Exploring Hybrid Caulks

Considering hybrid caulks can offer improved adhesion not only to other caulks but also specifically to silicones. These versatile products combine the strengths of different materials, providing enhanced bonding capabilities across various surfaces. By exploring hybrid caulking solutions, we can address adhesion challenges more effectively and ensure reliable performance in diverse sealing applications.

One example is:

- Utilizing a polyurethane-based hybrid caulk that offers exceptional adhesion properties on both traditional substrates and existing silicone sealants.

Techniques for Ensuring Caulk Adheres to Silicone

Compatible Primers

When applying silicone sealant over existing silicone, it’s crucial to use compatible primers or adhesion promoters. These substances enhance the caulk’s ability to adhere to the silicone surface. For instance, if we’re re-caulking a bathtub with silicone sealant, using a primer specifically designed for bonding new silicone caulk to old silicone can significantly improve adhesion.

It’s essential that we choose the right primer or adhesion promoter based on the type of silicone and the existing surface. This ensures that our new caulk adheres effectively without peeling or separating from the old silicone.

Proper Joint Design

To minimize stress on the interface between caulks and existing silicone, ensuring proper joint design and size is imperative. When reapplying caulk in areas such as kitchen countertops or window frames where there are expansion and contraction movements, creating a wider joint can help reduce stress on the caulking material.

By designing joints properly and considering movement dynamics, we can prevent premature failure of newly applied caulks over existing silicones. It’s like building a sturdy bridge that withstands various forces without collapsing – this approach ensures longevity and effectiveness.

Strong Bonding Capabilities

Selecting caulks with strong bonding capabilities is paramount when adhering to existing silicone surfaces. High-quality caulks formulated specifically for superior adhesion not only stick better but also provide long-lasting performance even when applied over older silicones.

We must look for products explicitly labeled as having excellent bonding properties when planning to apply them over an existing layer of silicone. This way, we ensure that our new application effectively sticks without compromising durability.

Addressing Damaged Silicone Surfaces with Sealant

Thorough Cleaning

Thorough cleaning is crucial. We must clean the damaged surface with a mild detergent and water. After rinsing and drying the area completely, we can proceed with repairing the damaged silicone.

We need to ensure that there is no residue or dirt left on the surface before applying new sealant. Any remaining debris can hinder the adhesion of the new silicone sealant, leading to potential issues in the future.

Suitable Primer or Bonding Agent

Applying a suitable primer or bonding agent before resealing damaged areas significantly enhances adhesion. The primer creates a strong bond between the old and new silicone layers, ensuring long-lasting results.

For instance, using a specific silicone adhesive primer designed for use with silicone sealants helps improve adhesion on problematic surfaces. This extra step increases our chances of achieving a durable and effective repair that withstands environmental stressors.

Closing Thoughts

We’ve delved into the complexities of silicone sealant adhesion, particularly focusing on its ability to stick to silicone surfaces. Through our exploration, we’ve uncovered valuable insights and practical tips for enhancing adhesion, preparing surfaces, and addressing common challenges. As we navigate the world of sealants and adhesives, it’s essential to remember that success often hinges on thorough preparation and strategic application. By implementing the techniques discussed, we can overcome adhesion issues and ensure a robust bond between silicone sealant and surfaces, empowering us to tackle our projects with confidence.

Let’s put our newfound knowledge into action and embark on our sealing adventures armed with the expertise we’ve gained. Whether it’s revamping a bathroom or tackling outdoor projects, let’s apply these insights to achieve durable and reliable results. Here’s to seamless adhesion and successful sealing endeavors!

Frequently Asked Questions

Will silicone sealant stick to silicone?

Yes, silicone sealant will adhere well to clean and dry silicone surfaces. Ensure proper surface preparation for optimal adhesion.

How can I enhance silicone to silicone adhesion?

To enhance adhesion, roughen the surface with sandpaper, use a primer designed for silicones, and ensure both surfaces are thoroughly cleaned before application.

What is the best way to prepare surfaces for silicone sealant application?

Clean the surfaces with a solvent or alcohol-based cleaner to remove any dirt, oil, or residue. Then, roughen the surfaces with sandpaper for improved adhesion.

Can caulk effectively adhere to existing silicone?

Caulk can adhere well to existing silicone if proper surface preparation is done. Clean and roughen the existing silicone before applying caulk for better adhesion.

How do I address damaged silicone surfaces with sealant?

If there are damaged areas on the silicone surface, it’s crucial to repair them first before applying new sealant. Use appropriate products and techniques based on the extent of damage.