MPC Coatings: Miracote Dry Mix 55lb Bag

$48.35

WHERE TO USE

- Concrete restoration and protection projects

- Resurfacing flawed or discolored concrete

- Bridge parapets and abutments

- Concrete elements in marine environments

- Renovations to stadiums and arenas

- Driveways, sidewalks, balconies and breezeways

- Pool decks and patios

- Use with MiraFlex XL for lead paint encapsulation

- Secondary containment and water tank liningsADVANTAGES

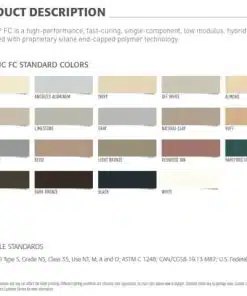

- Comes in 2 colors: Natural Gray or White

- Miracote Liquid Pigment can be added to white kit for wider color seletion

- NSF-61 Certified for use in potable water.

- Moisture vapor permeable – reduces potential for corrosion.

- Protects against penetration of water, chlorides and CO2.

- Ideal for exterior/interior, pedestrian and vehicular traffic.

- Mitigates corrosion when used with MiraPrime Aqua-Blok XL.

- Enhances appearance and curb appeal of concrete & masonry.

- Excellent adhesion to most substrate.

- Extensive choice of colors, textures and patterns.

- Zero VOC – meets LEED point criteria.

- Slip resistance built-in with most application methods.

MPC Coatings: Miracote Dry Mix 55lb Bag

MPC coatings Natural Gray Miracote MPC (Multipurpose Protective Coating) is a polymerized, two component, cementitious protective coating that can be applied over a variety of surfaces including concrete, masonry, metal, wood and tile. It consists of a unique rubber-like polymer liquid that is mixed with a proprietary cement and aggregate blend. Miracote MPC is then typically applied in two or more coats by trowel, brush, roller, spray or notched squeegee and back roll. Questions? Contact us

Designed for both exterior and interior use, Miracote MPC restores and protects concrete surfaces from the consequences of exposure to water and chloride intrusion, freeze thaw damage and carbonation. An extremely durable, cost-effective protective coating Miracote MPC is “breathable” and allows for the transmission of inherent moisture vapor within concrete without blistering or delamination. By lowering moisture content within the concrete, MPC Natural Gray helps reduce the potential for corrosion of steel reinforcement.

OVERVIEW OF INSTALLATION STEPS

• Surface Preparation – All surfaces to be coated must be clean, sound and free from any bond inhibiting substances including, but not limited to, grease, oil and any other contaminants or loosely adhered materials. For concrete substrates, a minimum surface profile of a CSP-3 or higher is required depending on overall substrate conditions and coating requirements. Concrete and other porous or absorptive substrates should be (SSD) saturated surface dry with no standing water at the time of the Miracote MPC application to the substrate.

• Mixing – Miracote MPC coatings must be mixed mechanically using a low- speed drill with a “Jiffy-type” or similar Miracote-approved mixing paddle in a clean mixing container. Pre-mix Liquid Catalyst first to re- disperse any polymer solids that may have settled on the bottom of the pail. When mixing, always pour the liquid catalyst component into the mixing pail first and slowly add the powder component. The mix ratio of powder to liquid may be slightly modified depending on whether a slurry or trowel-grade consistency is desired. Thoroughly mix the material until a uniform smooth consistency is achieved that is free of lumps and pockets of dry powder.

| Weight | 56 lbs |

|---|---|

| Dimensions | 20 × 5 × 5 in |

| Color | Natural Gray, White |

Related products

All Products

All Products

Aluminum

All Products

All Products

All Products