Conproco ECB 1G: Electro-Chemical Barrier

$362.16

ECB is a single component, low VOC, water-based protective coating which offers long-term protection for rebar from corrosion using three proprietary defense mechanisms. It requires that all loose scale be removed from the rebar but does not require the bright metal preparation.

117 in stock (can be backordered)

Conproco ECB 1G: Electro-Chemical Barrier

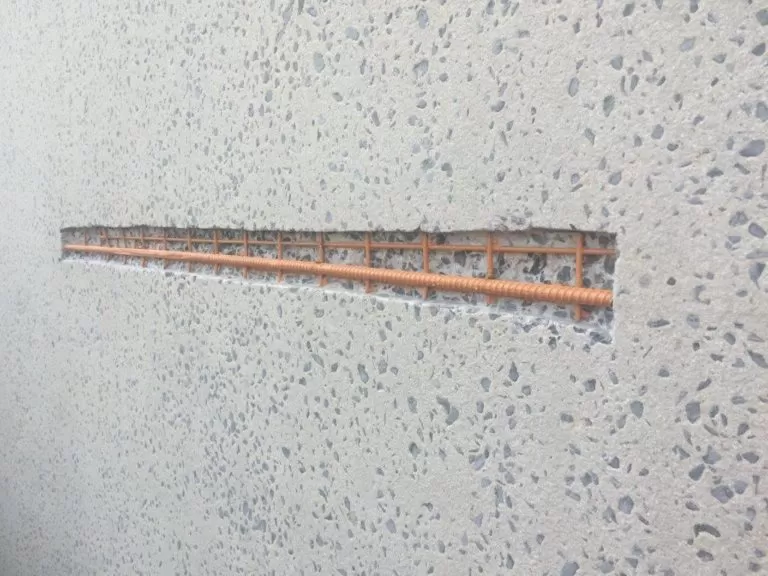

Conproco ECB, corrosion of reinforcing steel is the number one cause of failures in concrete. Getting 100% coverage of the rebar is essential to the long-term performance of the repair. Conproco ECB is a single component, zinc-rich acrylic coating. It does not require any mixing. All loose scale must be cleaned from the rebar. ECB can be painted or sprayed onto the steel as well as the concrete because it is not a bond-breaker. The orange color makes it easy to inspect for proper coverage. ECB can remain exposed for up to 30 days before either reapplying (no preparation required other than cleaning out any debris) or placing repair material. Because there is no mixing, there is no waste, simply replace the cover until the next use. Questions? Contact Us.

- Performance Characteristics:

Multiple defenses Barrier coating. Corrosion inhibitor. Prevent anode transfer. - Breathability

Water vapor permeable. - Ease of use

Single component, water based technology. Orange color clearly defines application area. - Stable

Does not produce destructive byproducts. - Long open time

Up to 30 days on steel before covering.

Up to 5 days on concrete before covering. - Thermal compatibility

Will not cause delamination due to temperature change. - Ease of application

Spray apply to increase production. - Ease of clean up

Clean equipment with water. - Environmentally friendly

Water based, low odor, non-flammable. - Surface Preparation:

Reinforcing Steel

Mechanically remove all scaling rust from metal.

Remove concrete around rebar to provide a minimum 3/4 inch clearance.

Remove concrete along the length of the bar until the exposed bar shows no sign of corrosion activity. - Concrete: Remove loose and deteriorated material, laitance, dirt, dust, oil and any surface contaminants that will inhibit proper adhesion.

- Priming ECB is a priming treatment.

- Mixing

Stir or mechanically mix using a low speed drill (400 – 600 rpm) until homogeneous. - Application

Brush or spray apply a uniform 7 mils. wet to all exposed steel.

For spray applications use a Graco 3500 or equivalent.

Brush or spray apply a uniform 7 mils. wet to prepared concrete surface when using as a bonding primer.

In severe environments a 2 coat application on steel is recommended.

| Weight | 38.44 lbs |

|---|---|

| Dimensions | 10 × 10 × 10 in |

Related products

All Products

All Products

All Products

All Products