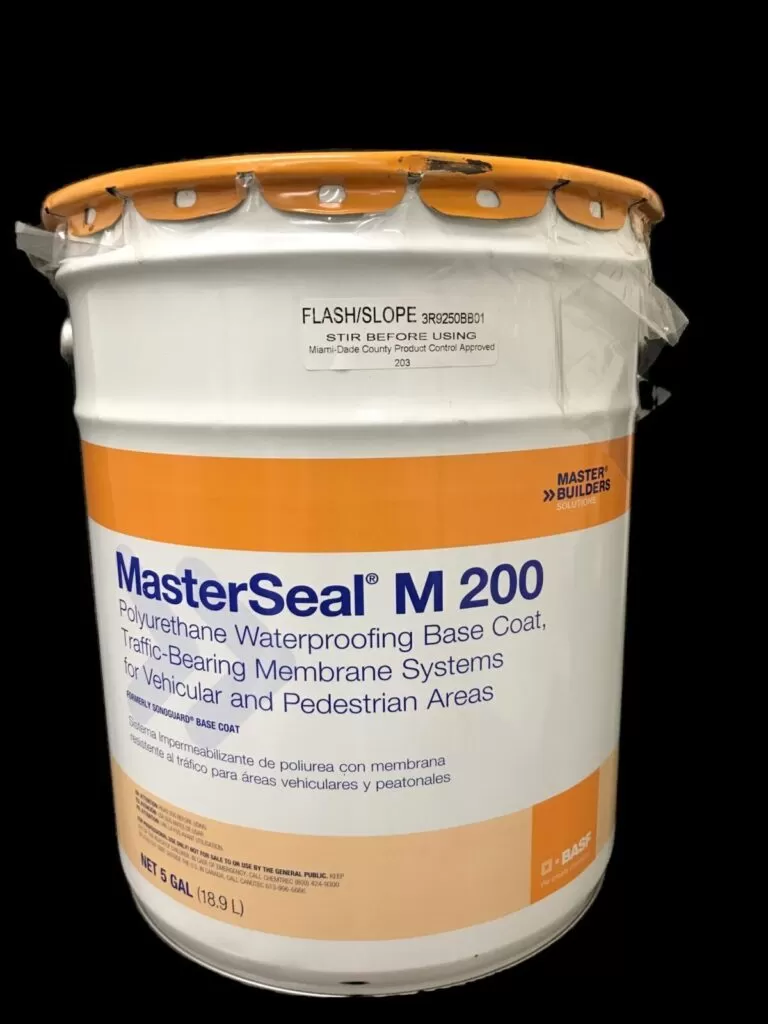

M200 Slope Masterseal: Masterseal Traffic Coating

$291.92

- Waterproof – Protects occupied areas below from water damage

- slip resistant to Increase pedestrian and vehicular traffic safety.

- Seamless membrane – bridges existing cracks

- Top coat UV resistant – suitable for external applications

- Range of top coat colours available – Attractive, decorative appearance

- VOC Content-MasterSeal M 200 selflevelling grade: 196 g/L of VOC.

- M 200 Self Level Version Here

11 in stock

M200 Slope Masterseal: Masterseal Traffic Coating

M200 Slope Masterseal is a liquid applied moisture-cure polyurethane seamless waterproofing membrane. As part of the MasterSeal Traffic 1500MD system creates a tough, continuously elastomeric properties achieve long term protection against water ingress. M200 Slope has a high skid resistance with aliphatic top coat ensures long life and suitability for public locations. Questions? Contact us.

RECOMMENDED USES

Waterproofing exterior surfaces subject to light vehicle and pedestrian traffic loads. Skid resistant textures are incorporated for safety as required. Substrates include concrete and incidental metal on car park decks. Provides durable attractive membrane to:- Park Decks, Balconies, plaza decks, rooftops, plant rooms, and can be used to recoat old membranes and copings.

APPLICATION

For information on surface preparation, priming, methods of application etc, refer to “Application Guide for MasterSeal Traffic 1500 MD available from your local BASF Construction Chemicals representative.

HOW TO APPLY SURFACE PREPARATION CONCRETE

1.Concrete must be fully cured (28 days), structurally sound, clean and dry (ASTM D 4263). All concrete surfaces (new and old) must be shot blasted to remove previous coatings, laitance and all miscellaneous surface contamination and to provide profile for proper adhesion. Abrasive shot blasting must occur after concrete repair has taken place. Acidetching is not permitted. Proper profile should be a minimum of ICRI CSP-3 (as described in ICRI document 03732.) For balconies and other pedestrian areas with limited space or access for shot-blasting, alternative mechanical methods can be used to achieve the recommended surface profile.

2.Repair voids and delaminated areas with BASF branded cementicious and epoxy patching materials. For application when fast-turn repairs are required, MasterSeal 350 can be used to repair patches up to 1.5″ in depth when used in aggregate slurry mix. Please refer to the MasterSeal 350 Technical Data Guide for proper application techniques.

3.All units must be applied within the

specified pot life.

MIXING

1.Transfer entire contents of pigment cans into Sonoguard Top Coat Tint-Base. Use a spatula or knife to remove all the pigment from the container.

2.With a slow-speed drill and Jiffy mixer, mix 4–6 minutes. The paddle blade must be kept below the surface of the Tint-Base to avoid whipping air into it.

3.To ensure consistent color throughout the pail, pour contents into separate container and continue mixing until all Tint-Base has dispersed.

4.When using multiple units, all units must be boxed to ensure color consistency

Masterseal

| Weight | 46.92 lbs |

|---|---|

| Dimensions | 15 × 15 × 18 in |

Related products

All Products

All Products

Waterproofing

All Products

All Products

All Products

Customer Reviews