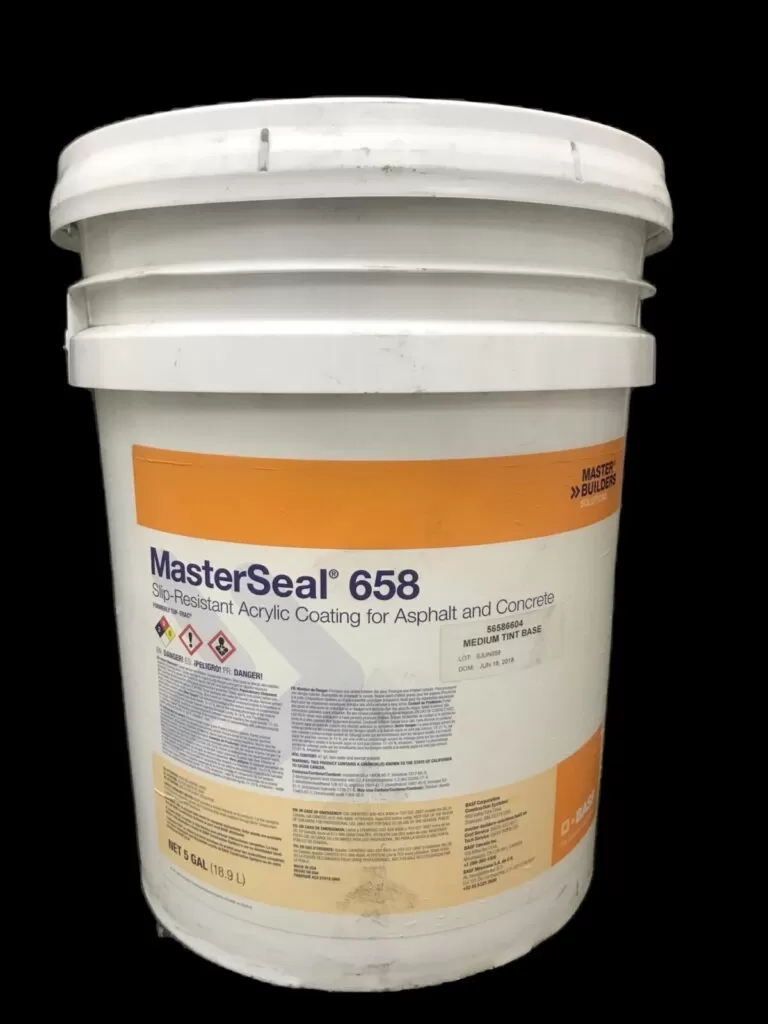

Masterseal 658 Neutral Tuf Trac: BASF Coating

$288.00

- Slip resistant safety finish makes MasterSeal 658 ideal for pedestrian traffic surfaces

- Excellent UV resistance

- Weather resistance for excellent durability and abrasion resistance

- Colors are non-glaring, making them ideal for tennis courts

- Available in custom colors for a wide range of color choices

Masterseal 658 Neutral Tuf Trac: BASF Coating

Masterseal 658 Neutral is a water-based, slip resistant acrylic coating for concrete and asphalt. Its accessories provide a complete coating system for outdoor recreation areas and surfaces with pedestrian traffic. Questions about Masterseal 658 Neutral? Contact Us.

SURFACE PREPARATION

CONCRETE SURFACES:

1.Floors must be structurally sound, fully cured, clean and dry.

2.Holes, crevices and spalled or disintegrated portions must be properly patched and filled; consult Technical Service for the appropriate concrete repair product.

3.All oil, grease, dirt, debris, mortar, paint drippings, curing and parting compounds and other surface treatments such as hardeners or sealers must be removed.

4.Mechanical surface profiling is the preferred floor preparation method. Mechanically profile the floor to a medium-grit sandpaper texture and remove curing and parting compounds and other surface hardeners and floor coatings. The key is to create a surface profile that will enable the coating to penetrate.

ASPHALT SURFACES

1.New asphalt must weather a minimum of 60 days before application of Masterseal 658. Rake out all cracks to remove accumulated sand, mud and weeds. Thoroughly hose down the surface to remove sand and sediment.

2.Scrub oil-soaked areas with a strong solution of detergent and hot water. Rinse area thoroughly with clear water, squeegee off excess, and allow to dry 1 to 3 days. When dry, check surface for any dirt or debris. If more than a trace is present, remove it with compressed air or a vacuum.

3.Repair holes and cracks with a suitable sealant, filler or patching material.

4.Press or squeeze patch firmly into place with a putty knife or trowel. Level off with adjacent surface.

5.Allow a minimum of 24 hours before topcoating. Do not apply in cracks wider than 1/2″ (13 mm).

PRIMING (CONCRETE ONLY)

Only required when Masterseal 658 is subjected to freeze-thaw environmental conditions.

1.Apply Masterseal 658 Primer at the rate of 250–300 ft2/gallon (6.1–7.4 m2/L). Apply 658 over the primer within 30 minutes while the surface still has a slight tack to it. In shady conditions apply 658 within 4 hours.

2.To improve the subsequent application of 658 acrylic coating, use approximately 1–2 lbs/gallon (0.12–0.24kg/L) of fine-grain, dry silica sand directly with MasterSeal 658 Primer; lightly broadcast the sand onto the material while it is still wet. This will prevent the roller or squeegee from slipping when MasterSeal 658 is applied.

APPLICATION

1.Stir MasterSeal 658 well before using. Whenever possible, apply MasterSeal 658 out of direct sun and during the cooler hours of the day.

2.MasterSeal 658 may be applied using a 3⁄8″(10 mm) roller cover or wide-blade rubber squeegee. Dampen the squeegee or roller before using and shake off excess water.

3.Pour MasterSeal 658 in a continuous stream along one edge of the area to be coated. In hot or sunny conditions, up to 1/2 gallon (1.9 L) of water per 5 gallon (18.93 L) pail may be added to improve the flow and application.

4.Spread evenly in short windrows. Continue pouring and spreading MasterSeal 658, overlapping 50% into the wet edge of the previous pass. For roller applications, finish the coating in one direction to prevent shading variations.

5.Allow the first coat to dry thoroughly before applying a second. For the best finish, apply the second coat at a right angle to the first.

Masterseal

| Weight | 20.4 lbs |

|---|---|

| Dimensions | 30.48 × 30.48 × 38.1 in |

| Color | Aluminum Gray (269-T), Beach Walk (6-P), Black (280-N), Brick Buff (99-T), Brick Red (167-A), Bronze (254-N), Brown Berry (207-T), Cameo (231-P), Cream (106-P), Chrome Gray (271-P), Desert Tan (92-P), Haze Gray (272-P), Irish Green (429-N), Limestone (273-P), Medium Bronze (258-N), Moonstone (222-P), Natural Gray (248-T), NP2 Off White (221-P), Off White (226-P), Parchment (241-P), Parkland (242-T), Pebble (246-P), Quall Brown (203-M), Quartz (455-P), Quick Silver (263-T), Redwood Tan (128-U), River Bend (116-T), Sesame (91-P), Shellside (186-P), Soft Blush (131-P), Special Bronze (259-N), Special Ivory (96-T), Special Tan (117-T), Special White (267-P), Steel Gray (277-U), Stone (251-T), Tan (98-T), White (452-P), Wine (177-A) |

Related products

All Products

All Products

All Products

All Products

All Products