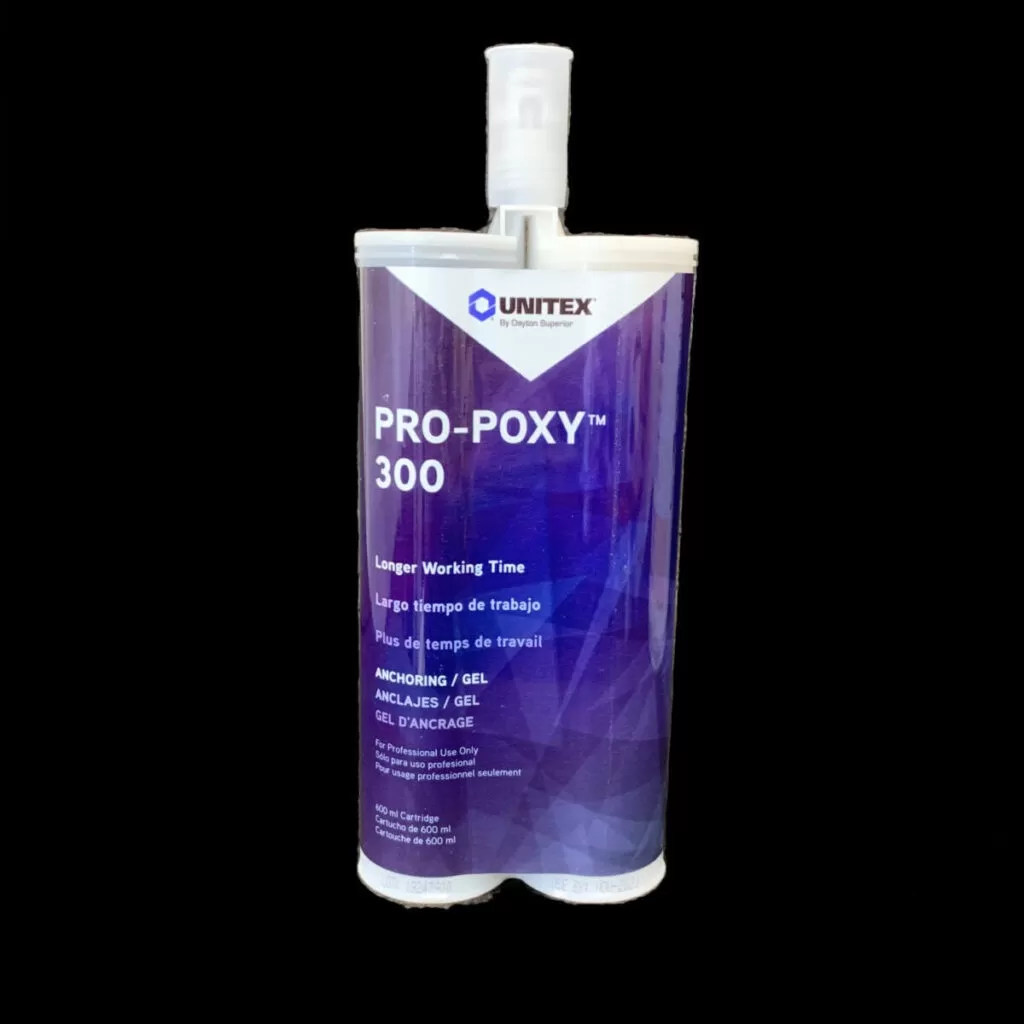

ProPoxy 300: Unitex Epoxy Concrete Bonding

$42.50

- High-strength structural adhesive

- Ideal for anchoring dowels, bolts, reinforcing steel and threaded rod

- Moisture tolerant

- Non-sag gel consistency

- Excellent adhesion

16 in stock

ProPoxy 300: Unitex Epoxy Concrete Bonding

Propoxy 300 is a two component, 100% solids, moisture tolerant, high modulus epoxy gel adhesive that meets ASTM C-881 and AASHTO M-235. Questions? Contact us

Propoxy 300 is ideal for anchoring bolts, dowels and reinforcing steel in concrete, it is also ideal for vertical and horizontal structural bonding and patching. Pro-proxy 300 may be used to seal cracks and set injection ports prior to injection grouting.

Surface Preparation:

Surface to be bonded must be clean and sound. Remove dust, dirt, grease, laitance, curing compounds and other foreign matter by sandblasting, mechanical abrasion or hydro blasting. For drilled holes, clean with a bristle brush.

Remove all water and dust with clean compressed air prior to installation. Air and surface temperature must be 40°F (5°C) or above.

Mixing:

Condition material to 65°- 85°F (18°- 29°C) before using, “pre-purging” the cartridge before putting on the static mixer to ensure uniform mixing. When using bulk packaging premix each component, then mix equal volumes of Part A and Part B for 3 minutes with a low speed drill, a jiffy mixer or paddle. Mix only what can be used during the pot life.

Placement:

Step 1: Drill hole in concrete using a rotarypercussion power drill (rotary-hammer drill) and a carbide-tipped SDS or SDS-Plus type drill bit complying with ANSI B212.15-1994, to the diameter and embedment depth adhering to minimum spacing, minimum edge distance, and minimum concrete member thickness.

Caution: Wear suitable eye and skin protection. Avoid inhalation of dust during drilling and debris removal.

Step 2: Blow out hole using oil-free compressed air at a minimum of 70 psi with a nozzle. While blowing air, insert the nozzle into the hole until in contact with the bottom for not less than one second, and then withdraw.

Step 3: Insert a cleaning brush for the proper drill hole diameter. Thrust the brush to the bottom of the borehole while twisting. Once the brush is in contact with the bottom of the hole, turn the brush one-half revolution, and then quickly withdraw the brush with a vigorous, twisting pull. Repeat.

Step 4: Repeat blow out of hole with air as per Step 2 above. Repeat step 3 followed by step 2.

Step 5: When using cartridge insert the cartridge into the extrusion tool, and attach the supplied mixing nozzle to the cartridge. Do not modify mixing nozzle. Prior to injection, dispense material through the mixing nozzle in a continuous bead until a uniform light gray color is achieved. Initial dispensed material will be darker gray in color and should not be used for installation. After uniform light gray color is achieved, insert the end of the mixing nozzle into the borehole until in contact with the bottom.

Dayton Superior Unitex Pro Poxy 300

| Weight | 2.5 lbs |

|---|---|

| Dimensions | 12 × 2 × 2 in |

Related products

Adhesive

Adhesives

Adhesives