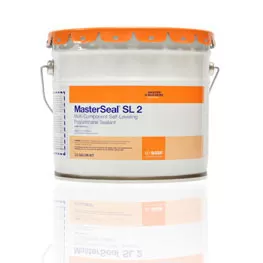

MasterSeal SL2 Slope Grade: Polyurethane 3 gal

$124.90

- Sonneborn SL 2 is a multi-component, selfleveling, elastomeric polyurethane sealant that is mixed and poured in place. 3 gal pail

- Abrasion resistant to help handle pedestrian and vehicular traffic

- Joint movement capability ±25% provides excellent flexibility for keeping moving joints weather tight

- Weather resistant, producing long-lasting weather tight seals

- Easy to gun and tool, speeding up application and making neater joints

- MasterSeal 905 accelerator available for use in cold climate applications to help speed initial cure

- No primer required for most construction materials, lowering installation costs

- Long pot life offers extended working time

- Chemical cure allows for faster turnaround time

Out of stock