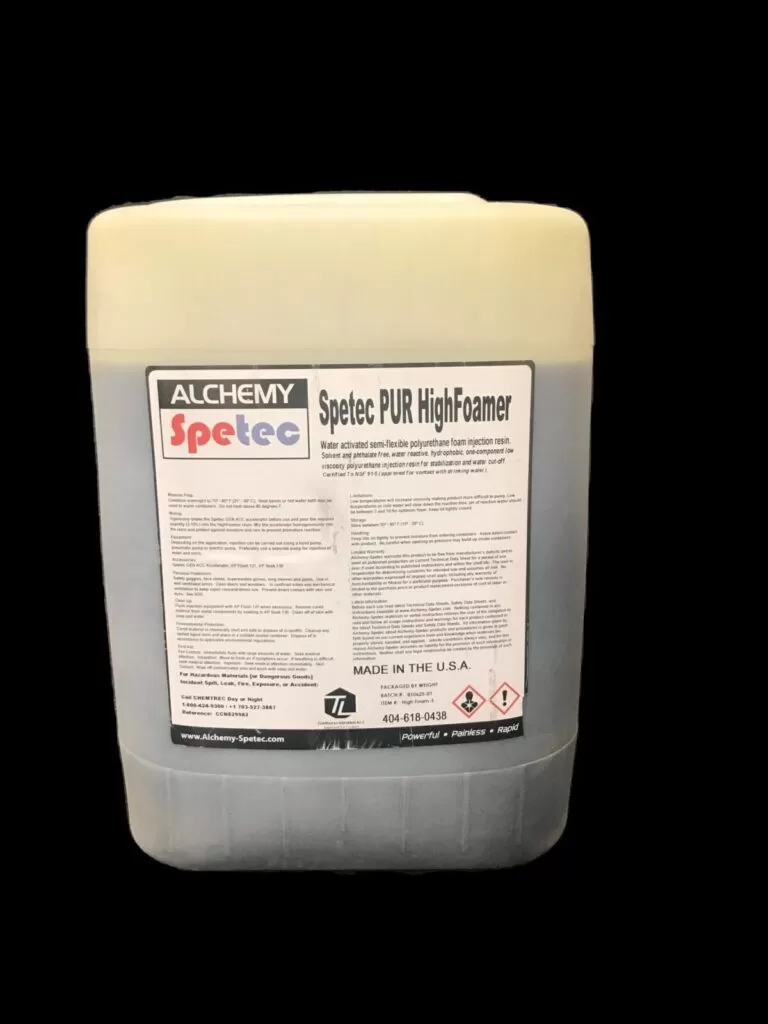

Spetec High Foamer: Spetec Resin 5 Gallon

$556.75

- Single component.

- Different reaction times are possible by adjusting the percentage of SPETEC® Gen Acc accelerator. To get an even faster reaction, there is also a SPETEC® Gen Acc Fast accelerator available.

- Cured polyurethane is rigid and exhibits high strength and good chemical resistance. (contact our technical service department for more information)

- Cured polyurethane is harmless for the environment and resistant to biological attack.

- Water cut-off of large flow and high pressure water leaks.

- Sealing foundations and sludge walls, sheet piles, secant pile walls.

- Stabilisation and water cut-off of large cracks, voids and gravel layers.

- Pre and post injections in mines, tunnels, pipe jacking, drill & blast and TBM applications.

- Injections in combination with cement-based grout.

- Crack and gravel nests injections in concrete structures.

- Water cut-off of sewer water leaks and sewer stabilisation.

- Injection of man holes.

5 in stock