Dryvit Reinforcing Meshes: Glass Fiber Mesh

Features:

- Durability

- Fully Tested

- Strength

Benefits:

- Provides impact resistance

- Warranted

- Provides continuity of surface to resist cracking

Dryvit Reinforcing Meshes: Glass Fiber Mesh

Dryvit Reinforcing Meshes have specially woven and treated glass fiber mesh is used with Dryvit base coats to provide strength and impact resistance. Strength and durability are a direct result of the weight of the mesh specified. Questions? Contact Us.

Dryvit Reinforcing Meshes when embedded in the Dryvit base coat mixture, the glass fiber reinforcing mesh provides continuity of surface to resist cracking and to increase impact resistance. The following guidelines are suggested:

Panzer 20: A 20.5 oz/yd2 (695 g/m2) mesh recommended for all ground floor and high traffic area applications. (Must be installed under Standard Plus or Standard Mesh).

Panzer 15: A 15 oz/yd2 (509 g/m2) mesh recommended for all ground floor and high traffic area applications. (Must be installed under Standard Plus or Standard Mesh).

Intermediate: A 12 oz/yd2 (407 g/m2) mesh recommended for the second story and above where a medium amount of traffic is anticipated, i.e., walkways, balcony areas, etc.

Standard Plus: A 6 oz/yd2 (203 g/m2) mesh recommended for the second story and above where added protection from such things as window washing equipment, ladders, etc. is desired.

Standard: A 4.3 oz/yd2 (146 g/m2) mesh recommended for all applications where no abuse from people, machines, window washing equipment, etc. is anticipated, typically second story areas and above.

Detail Mesh Short Rolls: A 4.3 oz/yd2 (146 g/m2) mesh available in 9 1/2 in (241 mm) widths. It is recommended for special shapes and irregular detail work.

Corner Mesh: A 7.2 oz/yd2 (244 g/m2) mesh recommended for additional impact resistance and for clean, crisp arises; outside corners; and prefabricated panel edges. (Must be installed under Standard Plus or Standard Mesh).

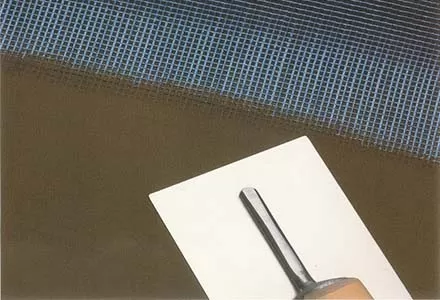

Prior to base coat/reinforcing fabric application, all insulation board irregularities greater than 1/16 in (1.6 mm) must be sanded flush. Apply the base coat to the entire surface of the insulation board. Fully embed the reinforcing fabric in the wet base coat troweling from the center to the edge of the reinforcing fabric so as to avoid wrinkles. The reinforcing fabric shall be continuous at all corners and lapped or butted in accordance with Dryvit’s recommendations. The overall minimum base coat thickness shall be sufficient to fully embed the mesh. The recommended method is to apply the base coat in two applications. All areas requiring higher impact performance shall be

detailed on the plans. The applications shall be installed in accordance with Dryvit’s recommendations. When using Panzer 15 or 20 Mesh, apply the Dryvit base coat mixture to the entire surface of the insulation board at a uniform thickness not to exceed 1/8 in (3.2 mm). Immediately embed the Panzer Mesh into the wet mixture working from the center to the edges until the mesh is fully covered and not visible. Edges of adjacent Panzer Mesh pieces shall be tightly butted but not overlapped. After it cures (minimum 24 hours), examine for projections and correct them as necessary to produce a flat surface. A layer of Standard or Standard Plus Mesh shall be installed as described in the first paragraph.