Pecora Dynaflex SC: 10oz Tube

$17.20

Dynaflex SC is a tamper resistant security sealant. It can be used for

interior expansion and control joints, window and door perimeter joints,

protrusions and penetrations, vents, around fixtures and in other interior

joints or openings of any kind (masonry-to-masonry, masonry-to-metal, or

metal-to-metal) requiring a sealant. Also, Dynaflex SC has good adhesion

to polycarbonate sheet for interior security glazing; however, priming is

required.

Pecora Dynaflex SC

If you are a contractor, homeowner, or business owner looking for an effective security sealant, then you need to consider using a tamper-resistant sealant. Find out more about the features of the Pecora Dynaflex SC: 10oz Tube and order online from Metro Sealant.

About Pecora DynaFlex

Pecora DynaFlex, a tamper-resistant security sealant, is specifically engineered for high-security installations like correctional complexes, where superior strength and durability are non-negotiable. Unlike ordinary sealants, DynaFlex is designed to achieve high tensile and abrasion resistance, essential for long-term performance in challenging environments. It adheres effectively to concrete block window perimeters, offering a rugged but flexible sealant solution that can withstand harsh conditions while maintaining its sealing properties. The tamper resistance of DynaFlex sets it apart, providing a reliable and robust barrier that significantly enhances the security of any installation. Pecora DynaFlex SC incorporates innovative Seamlock technology, ensuring secure and durable seals for a wide range of applications.

Similar Products

Backer Rod

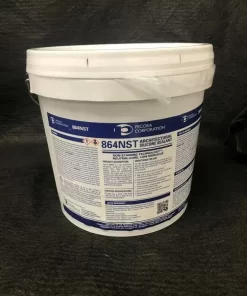

Dynaflex 1.5 Gallon

Dynapoxy EP 1200

Why Buy from Metro Sealant?

At Metro Sealant, we are proud to offer Pecora Dynaflex SC: 10oz Tube as one of our top-quality sealant products. This elastomeric sealant is designed for a variety of uses, from commercial and residential construction applications to industrial installations. Its superior flexibility, durability, and weather-resistant properties make it the perfect choice for any kind of job.

To learn more about our Pecora Dynaflex SC: 10oz Tube, contact us today!

| Weight | 1 lbs |

|---|---|

| Dimensions | 2 × 2 × 14 in |

| Color | Limestone, Tru White |

Related products

Multi component

All Products

Control Joints