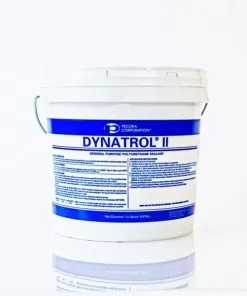

MasterSeal NP2: 1.5gal Non-Sag Polyurethane

$78.95

Masterseal Np2 features:

• Movement capability of 50% adds protection against unanticipated movement

• Weather resistant for long-lasting weathertight seals

• Easy to gun and tool to speed up application and make neater joints

• MasterSeal 905 accelerator available for use in cold climate applications to help speed initial cure

• No primer required for most construction materials, lowering installation costs

• Wide temperature application range makes MasterSeal NP 2 suitable for all climates

Available 11/3/22

See Sika 2C NS as a replacement product

MasterSeal NP2: 1.5gal Non-Sag Polyurethane

MasterSeal NP2 is a multi-component, highly flexible, nonpriming, high-performance polyurethane sealant. It has been successfully tested for joint movement of plus or minus 50%. 1.5 gal pail. Questions about Masterseal NP2? Contact Us.

APPLICATIONS:

• Interior and exterior

• Above and below grade

• Immersed in water

• Expansion joints

• Panel walls

• Precast units

• Aluminum and wood window frames

• Roofing

• Fascia

• Parapets

• Vinyl siding

• Store front assemblies

• Parking structures

JOINT PREPARATION:

1.Masterseal NP2 may be used in sealant joints designed in accordance with SWR Institute’s Sealants – The Professional’s Guide.

2.In optimal conditions, the depth of the sealant should be ½ the width of the joint. The sealant joint depth (measured at the center) should always fall between the maximum depth of ½” and the minimum depth of ¼”. Maximum recommended joint width is 3″.

3.In deep joints, the sealant depth must be controlled by closed cell backer rod or soft backer rod. Where the joint depth does not permit the use of backer rod, a bond breaker (polyethylene strip) must be used to prevent three-point bonding.

4.To maintain the recommended sealant depth, install backer rod by compressing and rolling it into the joint channel without stretching it lengthwise. Closed cell backer rod should be about 1⁄8″ (3 mm) larger in diameter than the width of the joint to allow for compression. Soft backer rod should be approximately 25% larger in diameter than the joint width. The sealant does not adhere to it, and no separate bond breaker is required. Do not prime or puncture the backer rod.

SURFACE PREPARATION:

Substrates must be structurally sound, fully cured, dry and clean. Substrates should always be free of the following: dirt, loose particles, oil, grease, asphalt, tar, paint, wax, rust, waterproofing or curing and parting compounds,

membrane materials and sealant residue.

CONCRETE, STONE, AND OTHER MASONRY

Clean by grinding, sandblasting or wire brushing to expose a sound surface free of contamination and laitance.

WOOD

New and weathered wood must be clean, dry and sound. Scrape away loose paint to bare wood. Any coatings on wood must be tested to verify adhesion of sealant or to determine an appropriate primer.

METAL

Remove scale, rust and loose coatings from metal to expose a bright white surface. Any coatings on metal must be tested to verify adhesion of sealant or to determine an appropriate primer.

MasterSeal

| Weight | 15.60 lbs |

|---|---|

| Dimensions | 10 × 10 × 10 in |

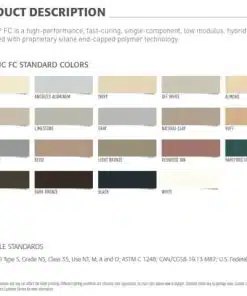

| Color | Tint Base, Limestone, Precast Gray |

Related products

Control Joints

Sealant Products

All Products

All Products