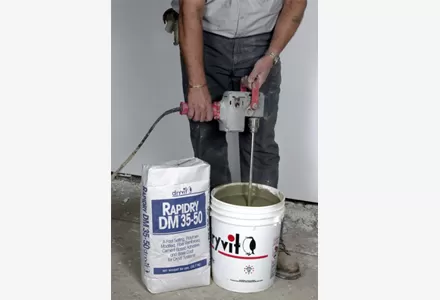

Dryvit Rapidry DM 35-50: Fast Setting Adhesive/Base coat

Features:

- Vapor Permeable

- Dry polymer modified

- Fast set adhesive and base coat

- One component

- Smooth consistency

- Temperature specific formulation

Benefits:

- Does not allow moisture to build up

- Excellent durability, adhesion

- Adhere EPS + base coat in same day

- Ready to use, just add water

- Trowels easily thus more production

- Use when air+wall temp is between 35°F-50°F

Dryvit Rapidry DM 35-50 : Fast Setting Adhesive/Base coat

Dryvit Rapidry DM 35-50 is a fast setting, polymer-modified, fiber-reinforced, cement-based, dry blend adhesive and base coat for use with Dryvit systems during colder weather. Questions? Contact Us.

Dryvit Rapidry DM 35-50 is used to adhere expanded polystyrene insulation board to approved substrates and to embed reinforcing mesh as part of the base coat. It is specifically formulated to use when job site temperatures will be between 35 ºF (2 ºC) and 50 ºF (10 ºC). It dries faster than traditional EIFS adhesives and base coats in colder weather, while providing adequate working time. Use of Rapidry DM 35-50 is not recommended if the temperature is to exceed 50 ºF (10 ºC). The rapid cure time of Rapidry DM 35-50 permits two installation steps to be completed in colder weather during one workday, i.e., insulation board installation and rasping or base coat and finish application.

Working Time: After mixing, the working time of Rapidry DM 35-50 is approximately 45-60 minutes. The higher the temperature the shorter the working time.

Drying Time: When used to bond expanded polystyrene insulation board to an approved substrate, enough time must elapse to allow Rapidry DM 35-50 to form a positive bond. The insulation board should not be rasped while Rapidry DM 35-50 is curing (see chart). When used as a base coat, finish can be applied after 4-5 hours under average cold weather drying conditions [40 ºF (4 ºC), 55% R. H.].

Job Conditions: Rapidry DM 35-50 is designed for applications in the temperature range of 35-50 ºF (2-10 ºC). Care must be taken to ensure that air and surface temperature is 35 ºF (2 ºC) or higher and such conditions are maintained during curing. The temperature of Rapidry DM 35-50 and water must be at or below 50 ºF (10 ºC) prior to mixing. Higher temperatures will shorten the pot life.

Temporary Protection: Shall be provided at all times until adhesive, base coat, finish and permanent flashings, sealants, etc. are installed to protect the wall from weather and other damage.

Substrate Preparation: Application is to Dryvit-approved substrates. Typically, these include exterior grade gypsum sheathing, DensGlass Gold®, or exterior cement boards, clean unpainted concrete, concrete block, brick and stucco. Substrates must be flat within 1/4 in (6mm) in any 4 ft (1.2 m) radius. Rapidry DM 35-50 is not approved as an adhesive for wood based sheathing.

| Weight | 50 lbs |

|---|