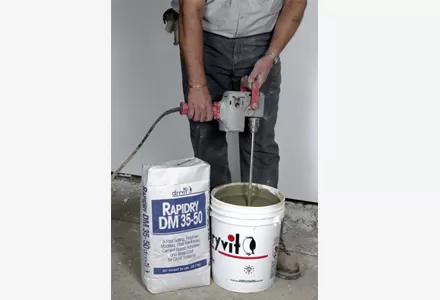

Dryvit Rapidry DM 50-75: Adhesive/Base Coat

$48.00

Features:

- Vapor Permeable

- Dry polymer modified

- Fast set adhesive and base coat

- One component

- Smooth consistency

- Temperature specific formulation

Benefits:

- Does not allow moisture to build up

- Excellent durability, adhesion

- Adhere EPS + base coat in same day

- Ready to use, just add water

- Trowels easily thus more production

- Use when air+wall temp is between 50°F-75°F

Out of stock

Dryvit Rapidry DM 50-75: Adhesive/Base Coat

Dryvit Rapidry DM 50-75 is a fast setting, dry mix, polymer-modified, cementitious adhesive and base coat for use with Dryvit systems. Questions? Contact Us.

Dryvit Rapidry DM 50-75 is used to adhere expanded polystyrene insulation board to acceptable substrates and to embed reinforcing mesh as part of the base coat for Dryvit systems. It is specifically engineered to use when job site temperatures will be between 50 °F (10 °C) and 75 °F (24 °C). It dries faster than traditional EIFS adhesives and base coats while providing an adequate working time. Use of Rapidry DM 50-75 is not recommended if temperature is to exceed 75 °F (24 °C). The rapid cure time of Rapidry DM 50-75 permits two installation steps to be completed during one workday, i.e., insulation board installation and rasping or base coat and finish application.

Adhesive: For application over sheathing substrates, use a stainless steel notched trowel with notches measuring 3/8 in (9.5 mm) wide, 1/2 in (12.7 mm) deep spaced 1 1/2 in (38 mm) apart. Apply the Rapidry DM 50-75 mixture on the back side of the insulation board and scrape the excess adhesive from between the adhesive beads. The adhesive beads shall be applied so that they run vertically when the insulation board is placed on the wall. For application over non-sheathing substrates, the notched-trowel application as described above is acceptable or a ribbon and dab application may be used. With a stainless steel trowel apply a ribbon of the Rapidry DM 50-75 mixture 2 in (51 mm) wide x 3/8 in (9.5 mm) thick around the entire perimeter of the insulation board. Place eight dabs of the Rapidry DM 50-75 mixture 3/8 in (9.5 mm) thick by 4 in (102 mm) in diameter approximately 8 in (203 mm) on center to the interior area. CAUTION: Do not install Rapidry DM 50-75 mixture directly on the substrate. Immediately place the insulation board on the substrate, ensuring that no Rapidry DM 50-75 mixture gets into board joints. Do not allow the Rapidry DM 50-75 mixture to form a skin before positioning the insulation board on the substrate as it will affect the bond strength.

Base coat: For base coat application, all insulation board irregularities greater than 1/16 in (1.6 mm) must be sanded flush. Apply the base coat to the entire surface of the insulation board. Fully embed the Dryvit reinforcing mesh in the wet base coat troweling from the center to the edge of the reinforcing mesh so as to avoid wrinkles. The reinforcing mesh shall be continuous at all corners and lapped or butted in accordance with Dryvit’s recommendations. The overall minimum base coat thickness shall be sufficient to fully embed the reinforcing mesh. The recommended method is to apply the base coat in two applications. All areas requiring higher impact resistance shall be detailed on the plans and described in the contract documents. The application shall be installed in accordance with Dryvit’s recommendations.

| Weight | 50 lbs |

|---|

Related products

All Products

All Products

All Products

Concrete Repair

All Products

All Products

Concrete Repair

Concrete Repair