Emcrete: High-Impact Elastomeric Concrete 5 Gallon

$279.20

5 Gallon Bucket Listed

Typical Uses

Some of the typical uses of Emcrete within EMSEAL expansion joint systems are:

Repair – To repair spalled gap edges in high load-bearing applications. The spalled concrete must be cut out using industry

standards for concrete repair. Once the gap edge has been cut and cleaned, the self-leveling Emcrete can be poured to form

ahorizontal elastomeric gap edge that is more resistant to spalling and gap edge deterioration.

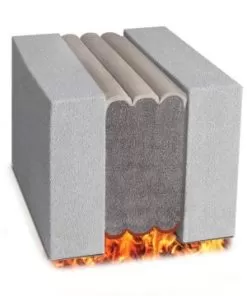

Elastomeric Concrete – To act as an elastomeric concrete where the possibility of spalling or cracking is a concern for standard

concrete or where existing spalls or potholes in concrete roadways, runways, bridges etc. is required.

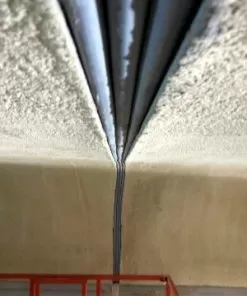

Leveling and Dampening – As a leveling bed and sound dampening support of the coverplates of EMSEAL SJS Seismic

Joint Systems systems. The SJS family of products from EMSEAL are coverplate systems secured to a precompressed foam and spline assembly. The coverplates ride on the deck surface. It is typical to form, cut or grind a shallow blockout on each side of the joint gap and fill this with Emcrete. This provides a surface that can be grinded to ensure that the coverplates do not rock and are fully supported over their entire contact area. Ensuring the plates are properly supported while absorbing the shocks of vehicular impact both contribute in attenuating sound.

Contact Us For Bulk pricing

36 in stock