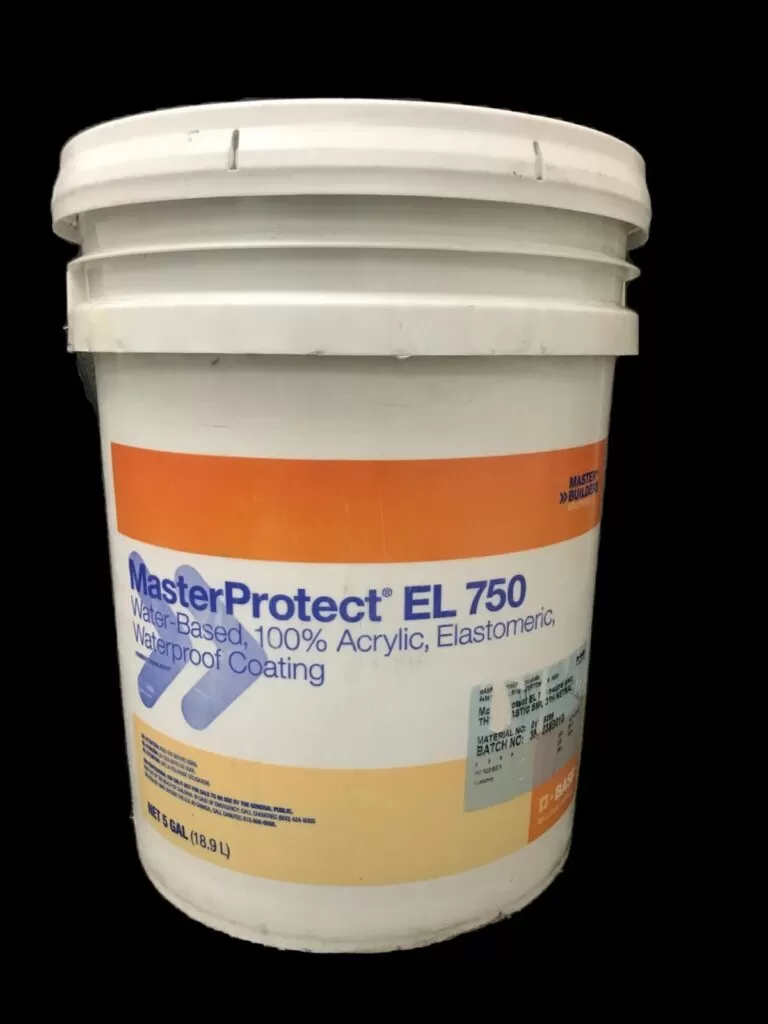

Masterprotect EL750 Coarse: Masterseal Waterproofing

$225.00

- Available in a broad range of colors and textures for design versatility

- Resists wind-driven rain; helps prevent water penetration into the substrate

- Breathable to allow water vapor to escape

- Excellent adhesion, bonds securely to substrate for long-term durability

- Excellent hiding power

- Textured formulations help improve aesthetics of irregular substrates

- Low VOC content for broad compliance across all regions

- Resistant to dirt pickup

- Also available in algae-resistant (AA) formula for versatility

Masterprotect EL750 Coarse: Masterseal Waterproofing

Masterprotect EL750 Coarse is a water-based, high-build, elastomeric, 100% acrylic waterproof coating for above-grade concrete, masonry, stucco and EIFS. Questions about Masterprotect EL750 Coarse? Contact Us.

HOW TO APPLY SURFACE PREPARATION

1.Surfaces should be clean and sound and free of all bond-inhibiting contaminants.

2.Concrete substrates should be fully cured.

3.Repair any holes, spalled and damaged concrete with appropriate Master Builders Solutions repair materials. Allow appropriate cure time prior to coating.

4.Remove any protruding concrete accessories and smooth out any surface irregularities.

5.High-pressure power wash surface (or abrasive blast on hard, dense surfaces) to create a profile of SP 3, per ICRI Guide 310.2.

6.Some stains may require chemical removal. Neutralize any cleaning compounds used and rinse with clean water.

7.Check adhesion of old coatings according to ASTM D 3359, Measuring Adhesion by Tape Test Method A.

8.Remove any blisters or delaminated areas and sand edges to smooth rough areas and provide transition to old paint areas. 9.Treat cracks greater than 1 ⁄32″ with MasterProtect FL 746 or MasterProtect FL 748. Treat cracks larger than 1/4″ as expansion joints and fill with appropriate Master Builders Solutions sealant.

10.New CMU must have a base coat of MasterProtect FL 749.

MIXING

1.Prior to use, mix MasterProtect EL 750 at slow speed with drill and mixing paddle to ensure uniform color and texture, and to minimize air entrapment.

2.In multi-pail applications, mix the contents of each new pail into the partially used previous pail to ensure color consistency and smooth transitions from pail to pail.

APPLICATION

1.Masterprotect EL750 is meant to be applied as a two-coat system, achieving a total dry-film thickness (DFT) of 16–20 mils (0.4–0.5 mm).

2.Apply MasterProtect EL 750 by brush, spray, roller, or spray-and-backroll.

3.Maintain proper uniform wet-film thickness (WFT) during application to ensure the performance characteristics desired (see yield rates section).

4.Always work to a natural break and maintain a wet edge during application.

5.For uniformity of color and texture, application techniques must be consistent throughout the project.

Masterseal

| Weight | 48 lbs |

|---|---|

| Dimensions | 12 × 12 × 16.5 in |

| Base | Medium Base, Neutral Base, Pastel Base, Ultra (Deep) Base |

Related products

Waterproofing

All Products

All Products

All Products

All Products

All Products

All Products