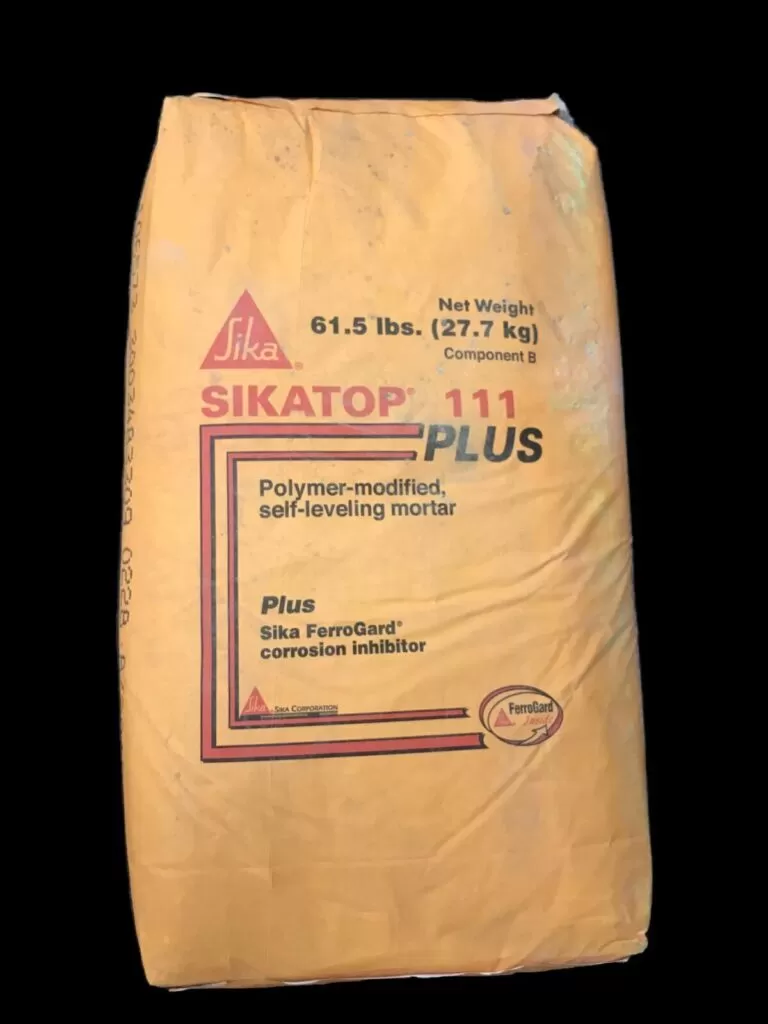

Sikatop 111 Plus: Two Component Corrosion Inhibitor

- Extremely low shrinkage proven by four industry standard test methods

- High compressive and flexural strengths Increased freeze/thaw durability and resistance to deicing salts

- Increased density – improved carbon dioxide resistance (carbonation) without adversely affecting water vapor transmission (not a vapor barrier)

- Enhanced with Sika FerroGard®-901, a penetrating corrosion inhibitor – reduces corrosion even in the

adjacent concrete

Part A: Safety Data Sheet

Part B: Safety Data Sheet

Sikatop 111 Plus: Two Component Corrosion Inhibitor

SikaTop 111 Plus is a two-component, polymermodified, Portland cement-based, fast-setting, screed mortar. It is a high performance repair mortar for horizontal, vertical and overhead surfaces in form and pour applications. It offers the additional benefit of Sika FerroGard 901, a penetrating corrosion inhibitor included in its formulation. Questions about Sikatop 111 Plus? Contact Us.

▪ On grade, above grade, and below grade concrete Horizontal surfaces (e.g. for spall repairs on flat work, or as an overlay): pour and screed

▪ Vertical and overhead surface repairs when formed and poured, or formed and pumped with an appropriate pump

▪ Structural repair material for water and wastewater treatment plants, parking facilities, industrial plants,

walkways, bridges, tunnels, dams, abutments, floors and balconies

▪ Approved for repairs over cathodic protection systems

▪ Free flowing repair mortar for hard-to-reach areas

▪ Filler for voids and cavities Repair of substrates such as concrete, mortar, and masonry

SURFACE PREPARATION: concrete surfaces must be clean and sound. Remove all deteriorated concrete, dirt, dust, oil, grease, contaminants and other bond-inhibiting materials from the area to be repaired.

▪ Be sure the repair area is not less than 1/2 inch (12mm) in depth for placement of a Neat mix. Be sure the repair area is not less than 1 inch (25 mm) in depth for placement of an Extended mix.

▪ Preparation work should be done by high pressure water blasting, scabbling, or other appropriate mechanical means. Obtain an exposed aggregate surface with a minimum surface profile of ±1/8 inch (3mm) [ICRI CSP-6 to CSP-7] on clean, sound concrete.

▪ To ensure optimum repair results, the effectiveness of decontamination and substrate preparation can be assessed by a Pull-Off test (i.e. a Tensile Adhesion test per ASTM C 1583).

▪ Saw cutting the perimeter edges of the repair area is recommended, preferably cut at a dovetail angle..

▪ Substrate should be saturated surface dry (SSD) with clean water prior to application. No standing water should remain during application.

| Weight | 48.12 lbs |

|---|---|

| Dimensions | 50.8 × 30.48 × 8.89 in |