Blog

Polyurethane Sealant: Your Ultimate Guide for Effective Use

I

t keeps your windows leak-proof or your wooden deck weather-resistant? The hero behind the scenes is polyurethane sealant! This versatile substance, born from some pretty nifty chemistry, has a wide range of uses applied across numerous industries. From construction to repair jobs, it’s become an essential tool in many trades.

Polyurethane sealants play a massive role in building and repairing structures. They’re like the glue that holds our world together (literally!). Whether it’s sealing gaps on your home’s exterior or keeping moisture out of important machinery, these sealants are up to the task. So next time you enjoy a dry and cozy indoor atmosphere during a rainstorm, take a moment to appreciate the power of polyurethane sealants!

Various Types of Polyurethane Sealants

One-Component and Two-Component Polyurethane Sealants

Let’s dive straight into the heart of the matter. sealants come in two flavors: one-component and two-component. It’s not rocket science, but it does make a difference.

One-component sealants are ready to roll right out of the box. They cure when exposed to moisture in the air, which means you don’t have to mix anything together before applying them. These are your go-to for quick fixes or small jobs where simplicity is key.

On the other hand, two-component polyurethane sealant requires a bit more elbow grease. You’ve got to mix and seal the two separate parts together before you can use them. The upside? They’re super durable and perfect for heavy-duty applications where strength matters more than speed.

Specialty Types: High Modulus, Low Modulus, and Hybrid Sealants

But wait, there’s more! Not all are created equal. Some have special properties that make them better suited for specific tasks.

High modulus caulk is tough as nails and have high adhesive strength. They’re ideal for heavy-duty joint and sealing jobs like construction joints, roofs, doors or large gaps in concrete where you need a strong caulking.

Low modulus sealants are flexible little things that can stretch joints and compress joints without breaking a sweat. These babies shine in dynamic joints most surfaces, joints or areas subject to movement since they can handle changing conditions without cracking under pressure.

Hybrid silicone polyurethane sealant is like getting the best of both worlds – it has excellent adhesion like a high modulus but is also flexible like a low modulus one. It’s practically the superhero of concrete polyurethane caulk!

Factors Determining The Choice Of A Specific Type

So how do you know which type of polyurethane sealant is right for sealing your job? Well, it depends on a few factors:

The size and nature of the job: Small joint work might only need a one-component while larger construction jobs could require a two-component.

The environment: Areas with lots of movement or changing conditions might be better off with low modulus or hybrid.

Your personal preference: Some folks prefer working with one type over another because they find it easier or more effective.

Remember, no single type fits all situations! So choose wisely based on your needs, not just what’s popular or readily available.

And there you have it – an overview on various types! Whether you’re fixing up your house or constructing skyscrapers, there’s definitely a perfect polyurethane out there waiting just for you.

Application Guide for Polyurethane Sealant

Pre-application Surface Prep

Before you dive into the world of polyurethane sealant bonding, it is clear it’s key to prep your surface like a pro. Think of it as cooking your favorite dish, if you don’t prep your ingredients right, the end result won’t be as tasty.

Clean the surface: Grab a brush and scrub away any loose particles or dust. A clean surface is crucial for the sealant to adhere properly.

Dry it up: After cleaning, ensure that the surface is completely dry. Any moisture can mess with the joint adhesion process.

Prime time: Depending on what you’re sealing, a primer may be necessary for improved adhesion.

Proper Application Techniques

Now that our ‘dish’ is prepped, let’s get down to business – applying that polyurethane sealant.

Cut and load: Cut off the tip of your sealant tube at an angle and load it into your caulking gun.

Test run: Do a quick test run on some scrap material to get a feel for how much pressure to apply.

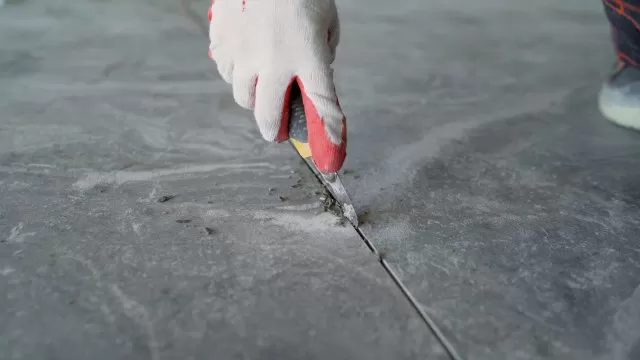

Apply with precision: Hold the gun at a 45-degree angle to the joint being sealed and apply consistent pressure for an even bead.

Smooth it out: Use a tool (or your finger) to smooth out the bead within five minutes before skinning starts.

Remember folks, practice makes perfect!

Post-application Care & Maintenance Tips

You’ve successfully applied your polyurethane sealant! Now what? It’s not just set-it-and-forget-it; here are some care tips:

Allow cure time: Let your project sit undisturbed until fully cured – typically 24-48 hours depending on humidity levels and temperature.

Regular checks: Keep an eye out for any signs of wear or damage over time so you can reseal if needed.

Clean up spills immediately: If you spill some sealant during application, use mineral spirits (for uncured sealant) or sandpaper (for cured) to clean it up promptly.

Top Brands of Polyurethane Sealants

Sika

Let’s kick things off with Sika. This brand has been around the block, making a name for itself in the sealant industry. Their polyurethane caulk is known for their high-performance. They’re your go-to if you need something that can withstand extreme weather conditions, resist aging, and adhere to most construction materials.

Unique Selling Point: High resistance to aging and weathering.

Customer Reviews: Users rave about its long-lasting performance and versatility.

Tremco

Next up is Tremco – another big player in the game. They are top-notch. Plus, they’ve got this unique ability to cure underwater – a lifesaver for those unexpected rainy days on the job. Tremco is in the silicone caulk game as well!

Unique Selling Point: Excellent flexibility and underwater curing.

Customer Reviews: Customers love its strong adhesion and flexibility.

Masterseal

Last but definitely not least is Loctite. These guys are all about speed! Their polyurethane sealants are fast-curing, saving you precious time on any project. And guess what? They’re paintable too! So you can seamlessly blend them into your surfaces without any hassle.

Unique Selling Point: Fast curing time and paintability.

Customer Reviews: Users appreciate its quick-drying nature and how easy it is to paint over.

Let’s take a closer look at how these brands stack up against each other:

BrandUnique Selling PointCustomer RatingSikaHigh resistance to aging & weathering4.5/53MFlexibility & Underwater Curing4/5LoctiteFast Curing & Paintability4/5

Each of these brands brings something unique to the table, whether it’s toughness, flexibility, or speed. But don’t just take our word for it! Check out some customer reviews online before making your choice.

Remember folks, choosing the right polyurethane sealant isn’t just about brand names; it’s about finding what works best for next project and your specific needs! So go ahead – roll up those sleeves, do a little research, and find that perfect polyurethane construction sealant that’ll make your next project a breeze!

Benefits and Drawbacks of Polyurethane Sealants

Durability, Flexibility, and Weather Resistance

A go-to choice for many due to their robustness. They’re like the Hulk of sealants – tough and enduring. With high tear strength and abrasion resistance, they can withstand the test of time without losing their charm.

Just as a gymnast’s flexibility and elasticity allows them to adapt to various physical challenges, so too does the flexibility of silicone caulk and polyurethane caulk. They have excellent elongation properties meaning they can stretch without breaks or the seal becoming damaged.

Ever seen how a duck’s feathers repel water and air and protect it? That’s similar to how polyurethane sealants resist weather conditions. These bad boys are resistant to extreme temperatures, UV radiation from sunlight, and even moisture in air.

Curing Time and Moisture Sensitivity

But hey, nobody’s perfect! Even superheroes have weaknesses. For polyurethane caulk, it’s curing time. The process is kinda like watching paint dry – it takes patience.

And then there’s moisture sensitivity during curing. Think of it as trying to bake a cake in an oven that keeps changing temperature – not ideal! If exposed to moisture before the seal is fully cured, water in these sealants’ cracks may bubble or foam up in the joint.

Comparison with Other Sealants

Let’s do some comparing now; think of it as a boxing match between different types of caulk!

In one corner we’ve got silicone sealant: great for adhesion but lacks in grit compared to our champ.

In another corner stands acrylic: easy application but falls short on flexibility when put head-to-head with polyurethane.

TypeDurabilityFlexibilityWeather ResistancePolyurethaneHighHighHighSiliconeMediumLowHighAcrylicLowMediumMedium

So there you have it folks! Like any other product out there, polyurethane has its pros (toughness, flexibility, weather resistance) and cons (curing time and moisture sensitivity). But at the end of the day, isn’t its resilience worth considering?

Safety Measures with Polyurethane Sealant

Protective Gear is Paramount

Hey, buddy! You know that old saying, “better safe than sorry”? Well, it’s a mantra to live by when handling polyurethane sealant. This stuff isn’t child’s play. It can be dangerous if mishandled. So, before you dive in headfirst, make sure you’ve got the right personal protective equipment (PPE).

Gloves? Check!

Safety goggles? Double-check!

Respirator mask? Triple check!

You get the drift. These aren’t just fancy accessories; they’re your best buddies against potential health hazards.

Watch Out for Health Risks

Speaking of hazards, let’s not beat around the bush here. Improper handling of polyurethane sealant is no small thing. It can lead to some serious health risks:

Skin irritation: That’s why gloves are a must-have.

Eye damage: Hence the goggles.

Respiratory issues: Ever wondered about the mask?

Ingesting or inhaling this stuff is like inviting trouble for dinner and asking it to stay overnight! So remember our PPE checklist from earlier? Stick to it like glue.

Disposal Done Right

Alrighty then! Now that we’ve covered safety during application let’s talk disposal. What do you do with leftover or expired product? Just chuck it in your regular trash bin and call it a day?

No siree! Safe disposal methods for unused or expired polyurethane sealant are crucial:

Never pour down drains.

Do Not toss into regular trash.

Follow local regulations for hazardous waste disposal.

Think about Mother Nature here folks! We don’t want any nasty stuff leaking into our environment now, do we?

So there you have it – safety measures with polyurethane sealant in concrete in a nutshell. Remember these points of action the next time you’re working with this material and keep yourself (and our planet) safe!

Cost-Effectiveness and Environmental Impact

A Penny for Your Thoughts

Let’s talk dollars and cents. Polyurethane sealant can seem like a big spend upfront. You might be tempted to opt for cheaper alternatives like silicone caulk or acrylic for your masonry. But hold your horses! Over time, polyurethane can actually save you a pretty penny.

Here’s the scoop:

Silicone caulk may cost less initially, but it doesn’t have the same skin as polyurethane. It tends to degrade under UV light exposure, meaning more frequent replacement.

Acrylic caulking, while also cheaper upfront, shrinks over time leading to gaps that require reapplication.

In contrast to silicone, polyurethane sealants are tough cookies. They resist UV light damage and maintain their flexibility even in extreme temperatures. This means fewer replacements and less maintenance – saving you money in the long run.

Going Green

Now let’s dive into the environmental footprint of polyurethane sealants. No sugarcoating here – producing any type of polyurethane construction sealant has an environmental impact. However, some options are greener than others.

The production process of polyurethane involves combining isocyanates and polyols which release carbon dioxide (CO2) – a greenhouse gas contributing to global warming. But before you jump ship consider this:

Polyurethanes are incredibly durable (remember what we said about long-term savings?). This means fewer replacements and therefore less CO2 emissions from production over time.

Many manufacturers are shifting towards using bio-based or recycled isocyanates and polyols reducing the carbon footprint of production.

So while not perfect, compared to other alternatives with similar performance characteristics, have a smaller environmental footprint when considering their life-cycle impact on the air and water.

To sum it up: Yes, there’s an initial investmentboth financially and environmentally speaking. But if we’re playing the long game (and who isn’t?), they offer cost savings through their durability and have a comparatively smaller environmental footprint due to fewer replacements needed over time.

So next time you’re faced with choosing between sealant remember: Don’t be penny wise but pound foolish!

Future Trends in Polyurethane Sealants

With their variety and versatility, are here to stay. From the various types available for different applications, to the top joint brands offering quality products, it’s clear that polyurethane sealants have carved a niche for themselves.

They’re not just about sticking joint together; they bring several benefits to the table. Their flexibility and resistance to elements make them a go-to choice for many. But remember, they do come with a few drawbacks like difficulty in cleaning and potential health risks if not handled properly.

When using caulk, safety is paramount. Always follow the application and installation guide and adhere to safety measures. And while they may seem pricey initially, their cost-effectiveness over time coupled with their full lifespan and minimal environmental impact makes them worth every penny.

So what’s next? The future of polyurethane sealants looks promising as trends point towards more eco-friendly caulk and advanced technologies enhancing performance further. So whether you’re a DIY enthusiast or professional builder, keep an eye out – there’s always something new on the horizon!

Ready to get started? Explore today and find the perfect polyurethane sealant that fits your needs!

FAQs

What are some top brands of polyurethane?

Some of the top brands are Tremco, Pecora, Sika, and Masterseal.

Are there any safety measures I should be aware of when using caulk

Yes! Always use gloves when applying the sealant and ensure good ventilation during application.

What are some drawbacks of using polyurethane?

They can be difficult to clean up after use and improper handling can lead to health risks.

How cost-effective are these?

While initial costs may be high compared to other types of adhesives/caulk, their durability makes them cost-effective over time.

Are there environmentally friendly options available?

Yes! Many manufacturers are now producing eco-friendly versions of their products without compromising on performance.

What does the future look like for polyurethane?

The future looks bright with trends pointing towards more sustainable caulk along with improvements in technology details enhancing product performance even further.

Where can I buy polyurethane sealant from top brands?

Well for one, we here at Metro Sealant carry the majority of brands of various caulks, sealants, coatings, and more. However, in order to prevent appearing biased, you can also get these from sites like Buildsite, Acehardware, or Home Depot. Though they aren’t specialized in sealant and may or may not have what you need.