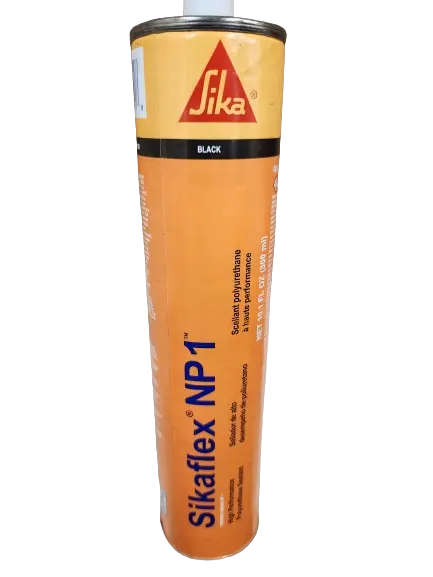

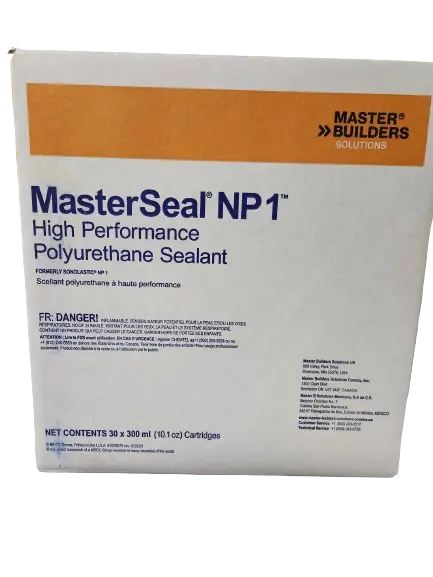

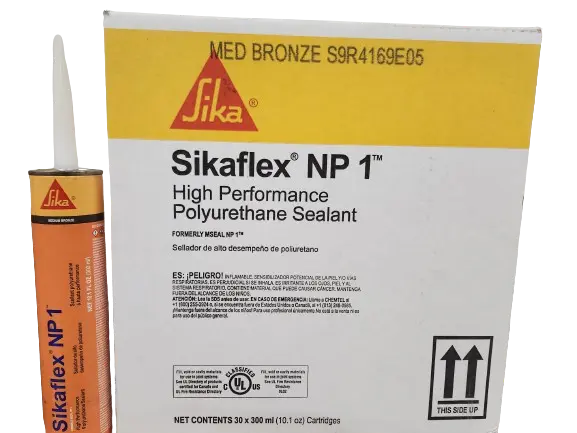

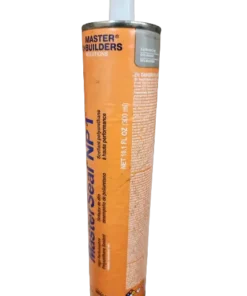

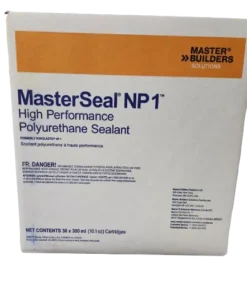

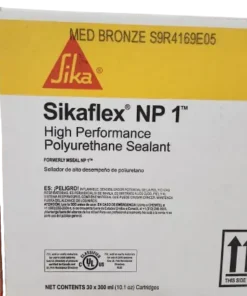

Sikaflex NP1 Caulk: Polyurethane 10.1oz Tube (Formerly Masterseal NP1)

$6.75

- One-component, elastomeric, paintable, gun-grade polyurethane sealant

- Weather resistant; provides long lasting weather tight seals

- Wide temperature application range; suitable for all climate conditions

- Suitable for water immersion *

Do you want a highly advanced sealant that offers superior adhesion and flexibility for interior and exterior applications? Find out more about the features of the master seal NP1 Caulk NS Polyurethane 10.1 OZ Tube and order online from Metro Sealant.

About the Masterseal NP1 Caulk NS Polyurethane 10.1 OZ Tube

The Masterseal NP1 Caulk NS Polyurethane 10.1 OZ Tube is the perfect solution for sealing and bonding various surfaces. This high-performance sealant provides superior adhesion, flexibility, and durability for inside and outside applications. It can bond wood, metal, ceramic tile, concrete, masonry, glass, and more. The product is also paintable, making it ideal for any residential or commercial project that requires an aesthetically pleasing finish.

This caulking sealant is resistant to extreme weather conditions such as UV rays, temperature fluctuation, moisture, and water. It’s easy to use with no special mixing or other tools required; simply cut off the tip of the tube and apply it directly on your project surface.

Why Buy Masterseal NP1 Caulk NS Polyurethane 10.1 OZ Tube from Metro Sealant?

At Metro Sealant, we strive to provide you with the highest quality products at the lowest prices. Our Masterseal NP1 Caulk NS Polyurethane 10.1 OZ Tube has superior adhesion strength and low VOCs, making it ideal for interior or exterior use in commercial and residential settings.

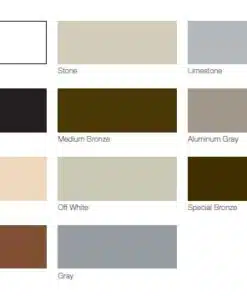

This product also provides excellent UV stability and resistance to wear and aging – so you know your job will last! Apart from that, it comes in 11 colors.

To learn more about our Masterseal NP1 Caulk NS Polyurethane 10.1 OZ Tube, contact us today!

NP1 Masterseal Sealant Is an Excellent All-Around Polyurethane Sealant

| Weight | 1 lbs |

|---|---|

| Dimensions | N/A |

| Color | ALUMINUM GRAY, BLACK, GRAY, LIMESTONE, MEDIUM BRONZE, OFF-WHITE, REDWOOD TAN, SPECIAL BRONZE, STONE, TAN, WHITE |

Related products

All Products

Aluminum

All Products

All Products

Pecora Sealant

All Products