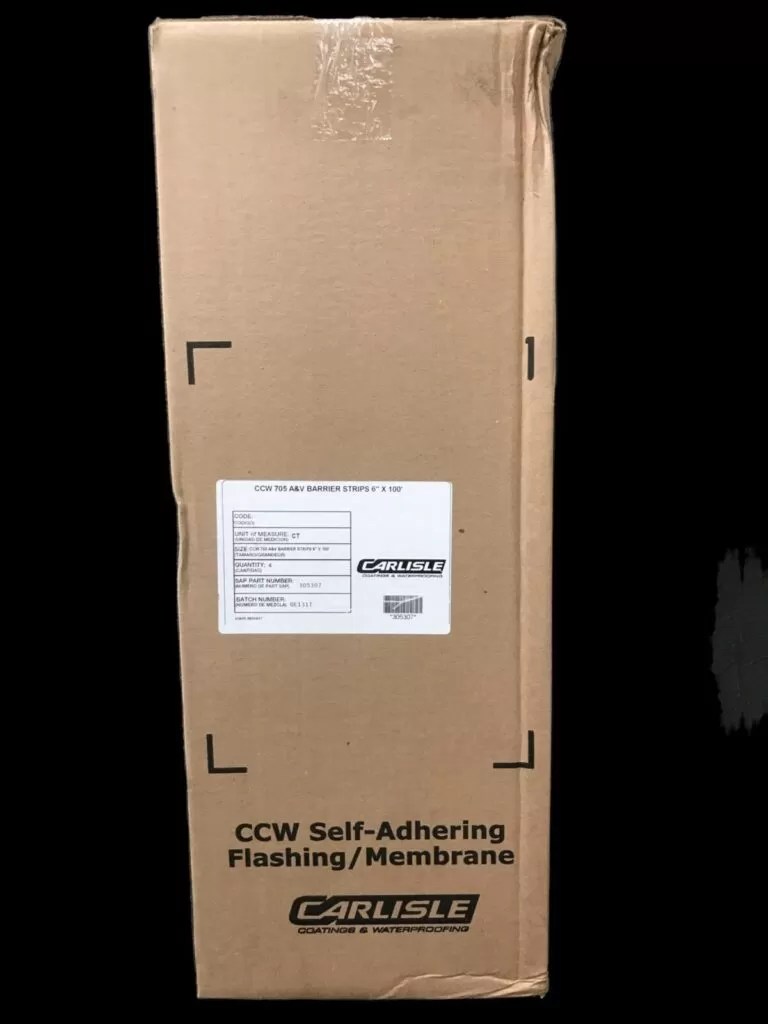

Carlisle CCW 705 Air Vapor Barrier

$53.40 – $232.50Price range: $53.40 through $232.50

• Printed facer provides easy product identification

• Factory-controlled composition provides uniform coverage and instant rain resistance after installation

• Self-adhering membrane provides easy, reliable installation; spray equipment or mil-thickness measurements required

• Membrane seals around fasteners and bridges cracks, providing an air and water-tight assembly

• CCW-705 is a warranted air & vapor barrier system from Carlisle Coatings & Waterproofing

Carlisle 705 Air Vapor Barrier

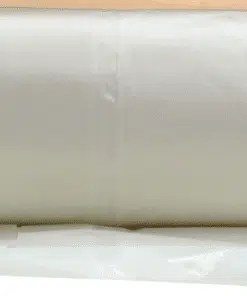

Carlisle 705 Air & Vapor Barrier is a 40-mil-thick (0.040″ inch) composite membrane consisting of a rubberized-asphalt adhesive laminated to a tough, dimensionally stable, smooth-surfaced poly film. Carlisle 705 Air & Vapor Barrier is provided in rolls of various widths lined with disposable silicone-coated plastic release film. The release film is removed to expose the adhesive as the membrane is pressed in place. 705 provides a complete barrier to moisture and air when adhered to an above-grade substrate. Cut sizes are also useful for other above-grade wall flashing applications. CCW-705 is cold applied and will adhere firmly when pressed against the substrate. Questions? Contact Us.

CCW-705 is designed for use in above-grade wall assemblies to function as an air, vapor and water barrier. CCW-705 can be applied over many common building materials including gypsum sheathing, concrete masonry unit (CMU), concrete, wood, structural steel, metal flashings, aluminum extrusions and rigid PVC (i.e. pipe/conduit, window frames). All substrates shall be prepared with a CCW contact adhesive to provide consistent adhesion of CCW-705 in jobsite conditions.

Standard installation of the product can be performed at when ambient and substrate temperatures are 40°F and above. Installation below 40°F, as low at 25°F, can be performed if the product is stored in a heated area until use and the laps are treated with CCW contact adhesive. Installations below 40°F are best addressed with CCW-705 XLT – low temperature adhesive formula. Consult the CCW-705 XLT product data sheet for further instruction. Install CarlIsle CCW 705 in horizontal rows or in vertical runs. Wipe dust or debris from film side of product with a clean, dry rag to assist in forming tight laps. Avoid forming wrinkles and air pockets. Press membrane firmly to substrate with a hand roller, especially at laps, corners and terminations. Overlap adjoining pieces of CCW-705 a minimum of 2 inches. Use narrower cut sizes for detailing. Sequence the installation to provide shingled laps. Membrane shall bear minimum 3 inches onto each side of transitions such as joints, angle changes and substrate changes. Membrane shall bear 6 inches minimum onto adjacent membrane systems such as foundation waterproofing or roofing. Apply a 1″ width X 40 mil thickness ribbon or Barribond or LM 800 XL over to field-cut edges, T-joints, reverse laps and terminations. After CCW-705 installation, Pressure-Sensitive Elastoform may be used to detail expansion joints and window/wall transitions. Consult CarlIsle CCW-705 Product Data Sheet for more information.

Need more Carlisle? We’ve got you covered.

Carlisle Barritech VP 5 gallon

Carlisle 800XL Tubes

| Weight | N/A |

|---|---|

| Dimensions | 8 × 8 in |

| Size | 4" x 100', 6" x 100', 9" x 100', 12" x 100', 18" x 100', 24" x 100', 36" x 75' |

Related products

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier