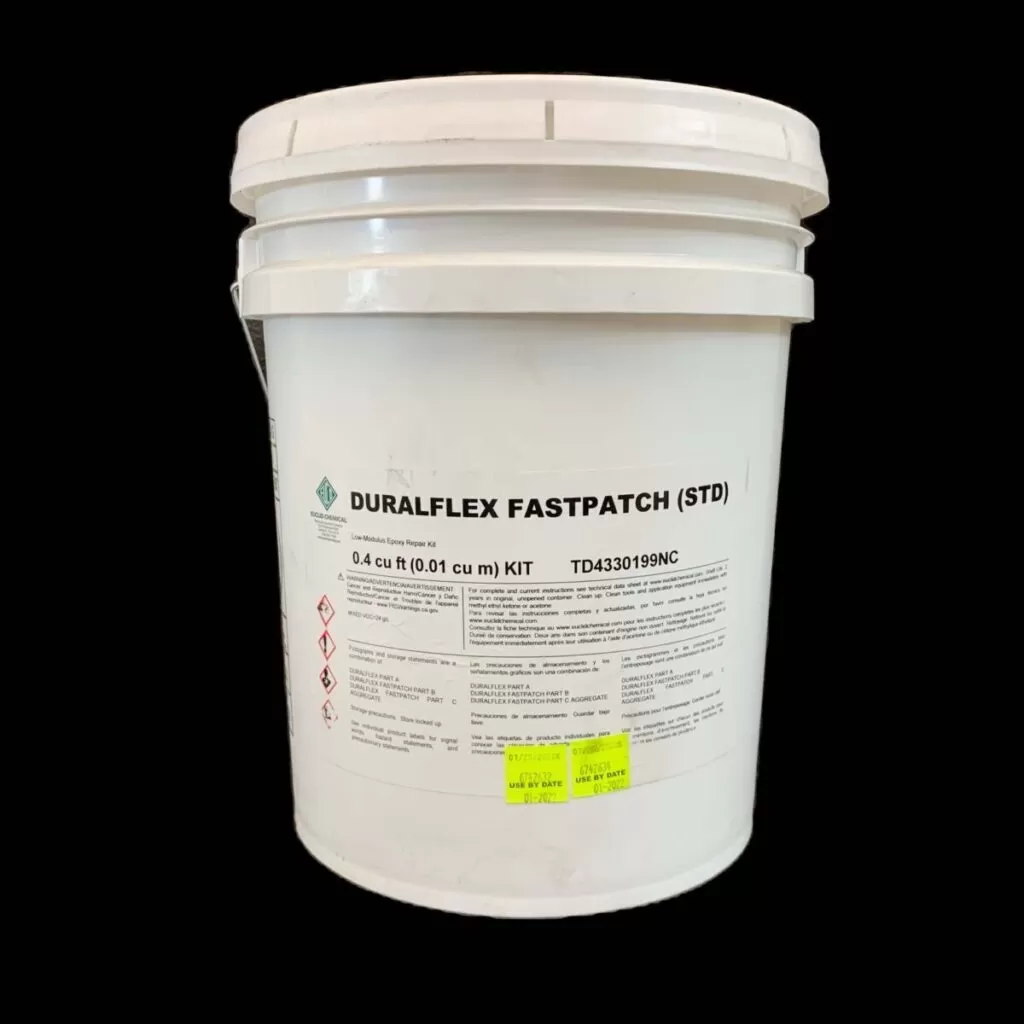

Duralflex Fastpatch: .4 CU Ft Euclid Epoxy Repair Mortar

$182.30 Original price was: $182.30.$148.29Current price is: $148.29.

- No measuring of components

- Pre-measured resin, hardener and specially blended “non-dusting” aggregate

- Low modulus resin binder used for stress relief and resistance to impact

- Resistant to thermal and mechanical movements

- Rapid cure, minimizes down time

- May be applied as low as 40°F (4°C)

- 33 colors available using color packs

- Warehouse floors

- Loading docks

- Mechanical rooms

- Parking decks and ramps

- Food storage areas

- Bridge decks and nosings

- Runways

Duralflex Fastpatch: .4 CU Ft Euclid Epoxy Repair Mortar

DURALFLEX FASTPATCH is a three-component, 100% solids, low-modulus, moisture insensitive, epoxy repair kit designed to provide a high strength, wear resistant surface to worn and damaged high-use floors. DURALFLEX FASTPATCH can be colored with EUCLID UNIVERSAL COLOR PACKS; available in 33 standard colors. Questions? Contact us

One kit yields 0.4 ft3 (0.011 m3). Applied at 1/4” (6.3 mm) thickness, one kit will cover approximately 18 to 20 ft2 (1.6 to 1.8 m2)

Surface Preparation: Concrete surfaces must be structurally sound, free of loose or deteriorated concrete and free of dust, dirt, paint, efflorescence, oil and all other contaminants. Mechanically abrade the surface to achieve a surface profile equal to CSP 3 – 5 in accordance with ICRI Guideline 310.2. Any exposed steel must be cleaned to a “white” metal finish.

Mixing: Remove the contents from the DURALFLEX FASTPATCH kit. Premix can containing Part A (base) and Part B (hardener) separately. Pour the entire contents of Part A and Part B into the supplied pail. Mix thoroughly using a slow speed 1⁄2” drill and a “Jiffy” mixer. Mix for 3 minutes. Make sure to scrape the bottom and sides of mixing container while mixing. Do not whip air into the product while mixing. Gradually add the supplied aggregate to premixed epoxy and blend thoroughly. BE SURE TO MIX THE EPOXY THOROUGHLY BEFORE ADDING THE AGGREGATE.

Application: For best results, condition the DURALFLEX FASTPATCH to 75°F (24°C) for at least 24 hours prior to application. Apply epoxy repair kit immediately after mixing with a trowel or screed. Material should be scrubbed into a dry surface for best adhesion. Trowel the material against the edge and gradually work toward the center of the repair area. Immediately after the mortar has been placed, aggregate can be broadcast into the wet resin to provide a more textured finish. Minimum application thickness of DURALFLEX FASTPATCH is 1/4” (6 mm); the maximum thickness is 3” (7.62 cm).

Finish your job with Euclid Epoxies:

Euclid Eucothane 3 gallon

Euco 700 Joint Filler

| Weight | 49.30 lbs |

|---|---|

| Dimensions | 15 × 15 × 18 in |

| Color | Standard, Light Gray |

Related products

Concrete Repair

All Products

Adhesive