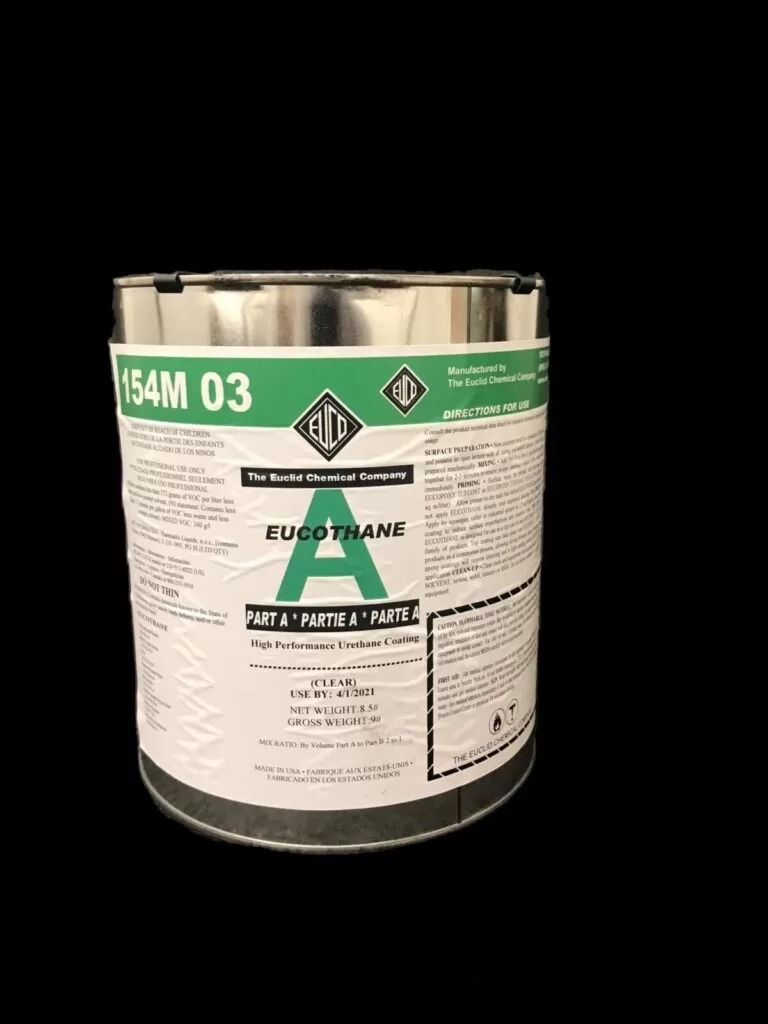

Euclid Eucothane 3G: Polyurethane Coating for Concrete

$755.00

• Airport hangar floors

• Manufacturing plants

• Bridge structures

• Laboratories

• Clean rooms

• Warehouses

• Truck/auto repair bays

• Walls/floors

Out of stock

Euclid Eucothane 3G: Polyurethane Coating for Concrete

Euclid Eucothane is a two component, solvent based, polyester/aliphatic polyurethane coating that offers outstanding abrasion resistance, excellent flexibility, color stability and weather resistant characteristics. It offers very good chemical resistance without compromising on aesthetics. Ideal as a topcoat for most Euclid Chemical epoxy, urethane and some masonry coatings, Euclid Eucothane provides excellent anti-graffiti properties. Questions? Contact Us.

• Excellent cleanability • Good chemical resistance • Anti-graffiti coating

Surface Preparation: The surface must be structurally sound, clean and free of grease, oil, curing compounds, soil, dust and other contaminants. See note in “Precautions/Limitations” section if coating is to be placed over old/existing epoxy or urethane coatings. New concrete and masonry must be at least 28 days old. Surface laitance must be removed. Concrete surfaces must be roughened and made absorptive, preferably by mechanical means, and then thoroughly cleaned of all dust and debris. If the surface was prepared by chemical means (acid etching), a water/baking soda or water/ammonia mixture, followed by a clean water rinse, must be used for cleaning, in order to neutralize the substrate. The Concrete Surface Profile (CSP) will be determined by the requirements of the epoxy coating applied before the EUCOTHANE application. Allow substrate to dry before coating application. Following surface preparation, the strength of the surface can be tested if quantitative results are required by project specifications. An elcometer or similar tensile pull tester may be used in accordance with ASTM C1583, and the tensile pull-off strength should be at least 250 psi (1.7 MPa). Do not apply epoxy or urethane coatings if there is excessive moisture in the concrete, or if the moisture vapor emission rate (MVER) is high. Before application of EUCOTHANE, perform either of these tests: ASTM F2170

– Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using In-Situ Probes, or ASTM F1869 – Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride. If the relative humidity is 70% or greater, or the MVER is 3 lbs/1000 ft2/24 hrs or greater, use a moisture mitigation system such as Dural Aquatight WB. After surface preparation and moisture testing, a test section application is recommended to confirm good adhesion and compatibility of the coating with the surface, and to confirm appearance and aesthetics.

Finish your job with Euclid Epoxies:

Duralflex Fastpatch Epoxy Repair Mortar

Euco 700 Joint Filler

| Weight | 40 lbs |

|---|---|

| Dimensions | 15 × 15 × 18 in |

Related products

All Products

All Products

All Products

All Products

All Products

All Products