GCP Hydroduct 660: 4ft x 50ft Roll

$510.85 Original price was: $510.85.$482.00Current price is: $482.00.

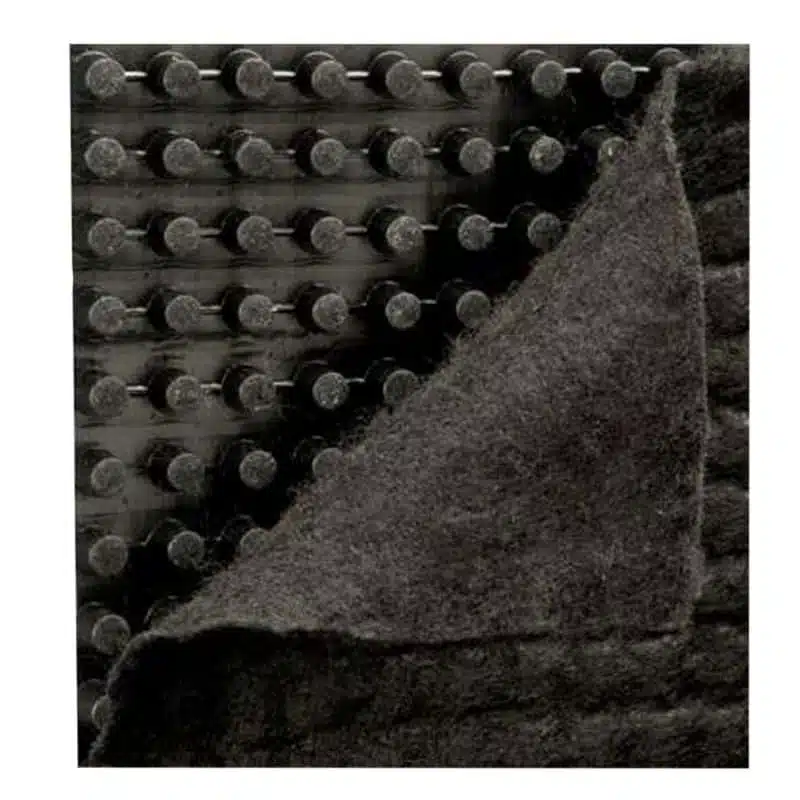

GCP HydroDuct 660 is a highly robust, preformed, 0.44 in. (11 mm) thick geocomposite drainage sheet system, comprising a heavy duty, studded polypropylene preformed membrane. This is covered on one side with a nonwoven, needle punched polypropylene filter fabric and on the other side with a smooth polymeric film. This film allows the HydroDuct 660 to be placed against waterproofing membrane and should not be removed.

Out of stock

GCP HydroDuct 660 Uses

GCP HydroDuct 660 Drainage Composite is designed to collect and transport water to drainage outlets. It can be used on all horizontal applications regardless of the type of overburden and serves as a combination drainage and protection course for all GCP waterproofing membranes.

The high strength, nonwoven geotextile is designed to maintain permeability while protecting the drainage composite from job site damage prior to, and during, the installation of the overburden. The high permittivity of the nonwoven geotextile facilitates the removal of water from a concrete pour, thus enhancing the concrete cure, as well as providing drainage after installation. The geotextile is securely bonded to the core to prevent intrusion of the fabric into the core during service. The high modulus backing film ensures compatibility when used with either Procor fluid applied waterproofing membranes, or with Bituthene waterproofing membranes.

Product Advantages

- Universal horizontal application—suitable for all overburdens including concrete

- Damage and creep-resistant—high compressive strength core resists traffic loads and site damage to maintain drainage flow

- High flow capacity—drains 23 gal/min./ft (286 L/min./m) width

- Enhances waterproofing—eliminates hydrostatic head build up

- Securely bonded fabric—restricts intrusion into core Polymeric backing film—compatible with both sheet and liquid waterproofing membranes

- Lightweight—easy to install without special equipment

- Simple, convenient, drainage and protection layer—robust membrane protection

Application Procedures

Safety, Storage and Handling Information:

All construction products must be handled properly. Safety Data Sheets (SDS) are available and users should acquaint themselves with this information. Carefully read detailed precaution statements on product labels and the SDS before use.

Installation

GCP HydroDuct 660 can be placed over waterproofing membranes, concrete or wood providing job site conditions allow the composite to remain as placed. Additional ballast consideration should be given in high wind exposures. A but all edges tightly with the excess geotextile placed over the adjacent roll in shingle fashion.

To secure HydroDuct 660 around protrusions, apply Preprufe Detail Tape around the protrusion in a picture frame configuration. Cut HydroDuct 660 to fit snugly around the protrusion. Press HydroDuct 660 core firmly into the Preprufe Detail Tape.

HydroDuct 660 should be covered promptly. Do not leave HydroDuct 660 exposed to sunlight for more than two weeks. Motor vehicles, construction equipment or other trades should not be allowed directly on the HydroDuct 660.

Coverage Rate

4ft x 50ft, see technical data sheet for more details!

For more information Contact Us

Related Products:

| Weight | 52 lbs |

|---|---|

| Dimensions | 15 × 15 × 48 in |

Related products

All Products

All Products

All Products

All Products

Waterproofing

All Products

All Products

All Products