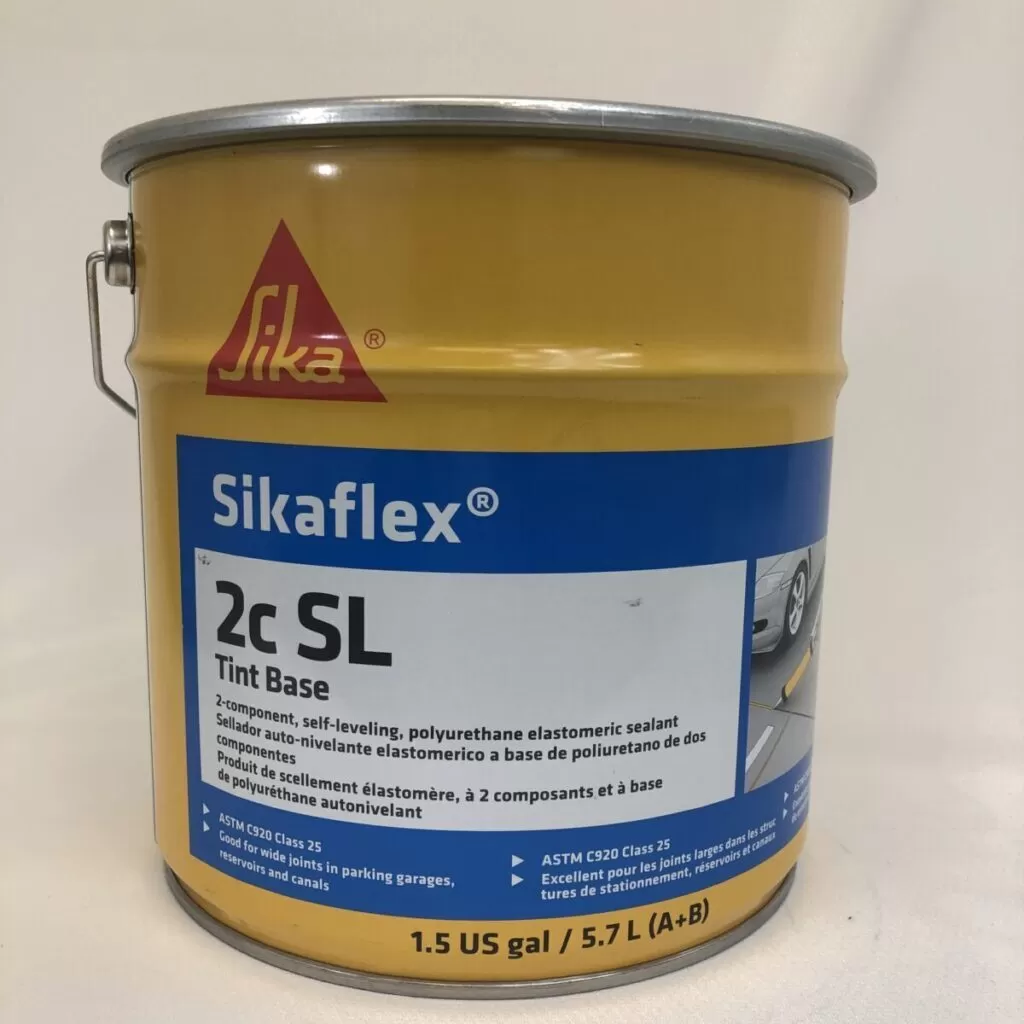

Sikaflex 2CSL 1.5 Gallon Tint Base: 2C-SL

$78.72

View the array of available color packs Here!

- High elasticity with a durable, tough and flexible consistency.

- True self-leveling properties.

- Self-leveling consistency, easy application in horizontal joints.

- Sealant can be used in non-moving joints that are exceeding 1/2 in. in depth thanks to chemical cure

- Exceptional adhesion to most substrates without priming.

- Capable of ±50% joint movement.

- Uniformity in color ensured via Color-pak system.

- Available in 35 architectural colors.

- Easy to mix.

- Exceptional cut and tear resistance.

- Jet fuel resistant.

- Paintable with oil-, water- and rubber-base paints.

114 in stock

Sikaflex 2CSL 1.5 Gallon Tint Base: 2C-SL

Sikaflex 2cSL is a premium-grade, 2-component, elastomeric, polyurethane-based sealant and is primarily a chemical cure in a self-leveling consistency. ASTM C-920, Type M, Grade P, Class 25, use T, NT, M, G, A, O, I. Federal Specification TT-S-00227E, Type 1, Class A. Anything we can help with? Contact us

2C does come in other sizes and variations:

Sika 2CSL 3 Gallon

Sika 2CNS Arctic

Recommended application temperatures 40–100 °F. Pre-conditioning units to 65–75 °F is necessary when working at extremity. Only place pre-conditioned units on working areas just before application. Apply sealant only to clean, sound, dry, and frost-free substrates. When the joint slot is at mid-point of its designed expansion and contraction, Sikaflex 2CSL should be applied into joints. To place, pour or extrude the SL grade in one direction and allow it to flow and level as necessary. If extruding, use a follower plate loading system or load mixed sealant directly into the bulk gun. Place the nozzle of the gun into bottom of the joint and fill the entire joint. Keep the nozzle deep in the sealant and continue with a steady flow of sealant preceding nozzle to avoid entrapping air. Keep away from overlapping sealant as this will entrap air as well. Tooling and Finishing Tool as needed. Dimension of joint should allow for a minimum of 1/4 inch and a maximum of 1/2 inch thickness for sealant. Proper design is 2:1 width to depth ratio. Removal Uncured material can be removed with an approved solvent. Strictly follow the solvent manufacturer’s instructions for use and warnings. Cured material can only be mechanically removed. In case of spillage, gather, absorb, and discard in accordance with current, applicable local, state, and federal regulations. Good joint design and proper application define the ultimate performance of Sikaflex-2c. Minimum depth in working joint is 1/4 in. Maximum expansion and contraction should not exceed 50 % of average joint width. Do not cure in the presence of curing silicones. Avoid contact with alcohol and other solvent cleaners during cure. Allow 3 days for cure to rest before subjecting sealant to total water immersion. Primer is required if sealant will be subjected to total water immersion. Avoid exposure to high levels of chlorine. (Maximum level is 5 ppm). Do not use it in the presence of moisture vapor transmission as this can result in formation of bubbles within the sealant. Avoid mixing sealant too much. When exposed to ultraviolet rays, white color has a tendency to yellow slightly. Light colors can yellow if exposed to direct gas fired heating elements. When overcoating: we recommend an on-site test to decide actual compatibility. Coatings, primers or rigid paints will crack when used over elastomeric sealants experiencing expansion or contraction. For desired color, add entire Sika 2C color pak of wanted color before use. Available colors can be seen here.

Warning: This product contains chemical(s) known to the State of California to cause cancer and/or to cause birth defects or other reproductive harm.

For more information go to www.p65warnings.ca.gov

| Weight | 18 lbs |

|---|---|

| Dimensions | 10 × 10 × 10 in |

Related products

All Products

Sealant

All Products

Concrete