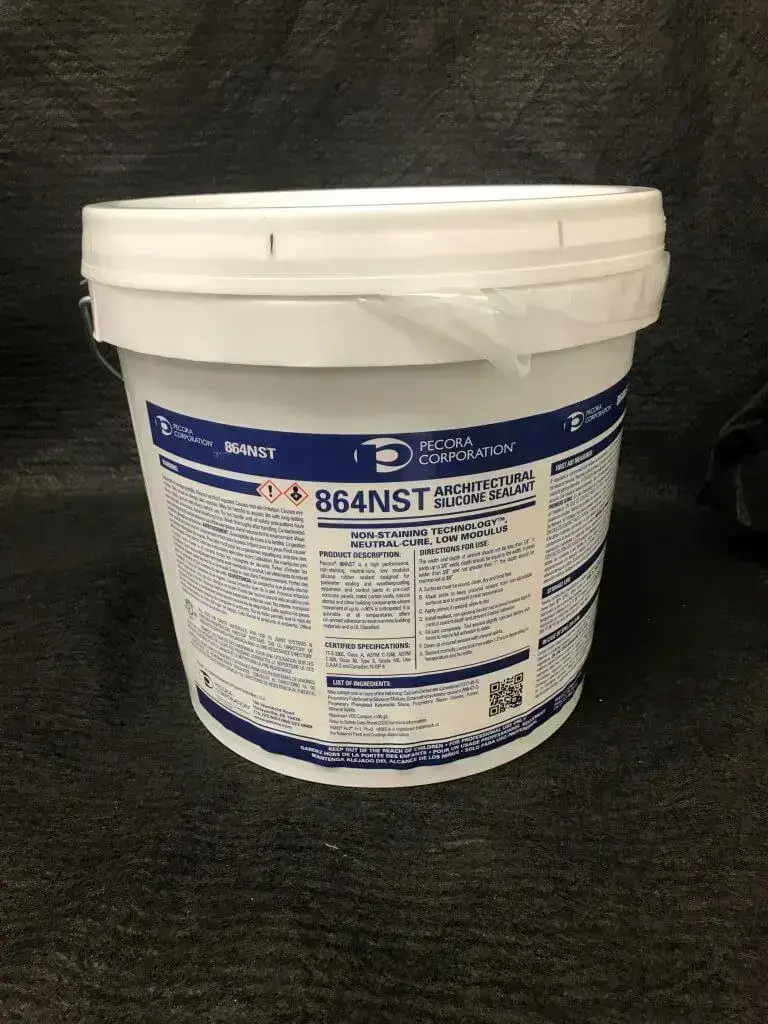

Pecora 864 NST: 2 Gal Silicone Sealant

$218.50

For sealing expansion and control joints in precast concrete panels, masonry and metal curtainwalls, natural stones, perimeter sealing of doors and windows, and other building components

Pecora 864 NST: 2 Gal Silicone Sealant

Pecora 864 NST is one-part, low-modulus, neutral-curing, high-performance silicone sealant that cures via atmospheric moisture to form a durable, flexible building seal. Pecora 864 NST will not stain natural stone such as marble and granite. Because of its low-modulus, high extension/compression and recovery properties, and its strong adhesion to most building materials, Pecora 864 NST performs exceptionally well under dynamic conditions accommodating long-term movement of ±50% in properly designed joints.

Limitations:

Pecora 864 NST should not be used in the following applications:

• Sealing horizontal decks, patios, driveway or terrace joints where abrasion or physical abuse is encountered.

• Sealing submerged joints or below the waterline in marine applications.

• In totally confined or air-free spaces.

• In designs that will be painted after application of the sealant. (Sealant should be applied after painting is completed).

• To surfaces with special protective or decorative coatings without prior consultation with Technical Services department.

• With building materials that bleed oils, plasticizers or solvents, i.e. impregnated wood, oil-based caulks, some vulcanized rubber gaskets or tapes, etc.

TECHNICAL DATA

Applicable Standards: Pecora 864 NST Silicone meets or exceeds the requirements of the following industry specifications; TT-S-230C, Class A. ASTM C-920, Class 50, Type S, Grade NS, Use G,A,M,O and CGSB-19GP-9, ASTM C-1248. Acceptance by U.S. Department of Agriculture for use in meat and poultry processing plants.

Joint Design: Proper sealant dimensions are critical when installing elastomeric joint sealants. Generally, a sealant width to-depth ratio of 2:1 is recommended. Dynamic joint conditions will require a minimum 1/4” width and 3/16” depth in order to maintain the sealant’s movement capabilities. For joints greater than 1”, consult Technical Services. Lap shear joints should have a bead width which is equal to or greater than the total anticipated movement. Small curtainwall panels and lites should allow a minimum width of 1/4” (6 mm) for the sealant bead. Larger panels for which a great deal of movement is expected should allow a minimum width of 1/2” (12 mm) for the sealant bead. Glazing of plastic lites and panels fabricated from plastic require larger than usual joint dimensions due to the plastics high coefficient of thermal expansion. The width of building expansion joints varies because of seasonal and daily changes in temperature. If Pecora 864 NST silicone cannot be installed when the design width is approximately halfway between the dimensional extremes, the designed joint must be at least twice the total anticipated joint movement. Good architectural practice calls for joint design of four times the anticipated movement due to construction tolerances and material variations.

INSTALLATION

Surface Preparation: Clean all joints and glazing areas by removal of foreign matter and contaminants such as oil, dust, grease, frost, water, surface dirt, old sealants or glazing compounds and any protective coating. Porous substrates and precast concrete panels using form release agents other than polyethylene film should be cleaned by grinding, saw cutting, blast cleaning (water or sand), mechanical abrading or a combination of these methods which will provide a sound, clean and dry surface for sealant application. Dust, loose particles, etc. should be blown out of joints with oil-free compressed air or vacuum cleaned. Metal, glass and plastic surfaces should be cleaned by solvent procedure or by mechanical means. Soap or detergent and water cleaning treatments are not recommended. Cleaning of all surfaces should be done on the same day on which the sealant is applied.

CAUTION: Solvents may be toxic and/or flammable. Refer to solvent manufacturer’s instructions or Safety Data Sheets (SDS).

Priming: Pecora 864 NST does not require priming on most common substrates. However, we strongly suggest adhesion pretesting, either in the field or our laboratory, on all porous substrates, particularly brick, as well as unusual building materials and other substrates where special coatings or surface treatments may impair optimum adhesion. Where primer is indicated, P-150 should be used on porous substrates and P-120 on special metal and plastic surfaces. All precast substrates require priming with P-225 primer. Also, Pecora offers complimentary adhesion and stain testing in its laboratory on actual field samples of substrate from the jobsite or on representative samples from the same lots. Contact Technical Services for details.

Joint Backing: Backer rod controls the depth of the sealant and allows it to be applied under pressure. Use a size that will compress 25%. Denver Foam open-cell polyurethane or reticulated (soft) polyethylene rod is recommended. Closed-cell polyethylene may be used but care must be taken not to puncture the rod which can cause outgassing or bubbling/blistering in the sealant. In joints too shallow for backer rod, use a polyethylene bond-breaker tape to prevent three-sided adhesion.

Application: All joints should be masked to ensure a neat appearance and prevent sealant applied outside the joint confines from imparting a discoloration to the substrate. Sealant should be applied in a continuous operation using sufficient pressure to fill the joint and make complete contact to the joint sides. Tool the sealant slightly concave using dry tooling techniques. Consult Technical Services prior to tooling with solvent. Do not tool with soap or detergent and water solutions.

Tool Time: (Initial skin): 15-25 minutes at 77°F (25°C), 50% relative humidity. Higher temperatures and\or humidity will shorten this time.

Cleaning: Immediately remove all excess sealant and smears adjacent to joints with mineral spirits. Also use mineral spirits for removing uncured sealant from equipment. Remove cured sealant by scraping, sandpapering, etc. (Caution: mineral spirits is flammable and toxic. Observe manufacturer’s precautions.)

Shelf Life: Pecora 864 NST has a shelf life of twelve months from date of manufacture when stored in unopened cartridges or sausages at temperatures lower than 80º F (27º C), or nine months in tightly sealed bulk packages at temperatures lower than 80º F (27º C).

Precautions: Use with adequate ventilation or wear an appropriate NIOSH approved respirator. Contact with uncured sealant or with vapors generated during curing may cause respiratory tract irritation. Contact with skin or eyes may cause irritation or allergic reaction. Avoid contact and wash thoroughly after handling. May be harmful if swallowed. Refer to Safety Data Sheet (SDS) for more information.

Questions? Contact Us

| Weight | 15.6 lbs |

|---|---|

| Dimensions | 12 × 10 × 10 in |

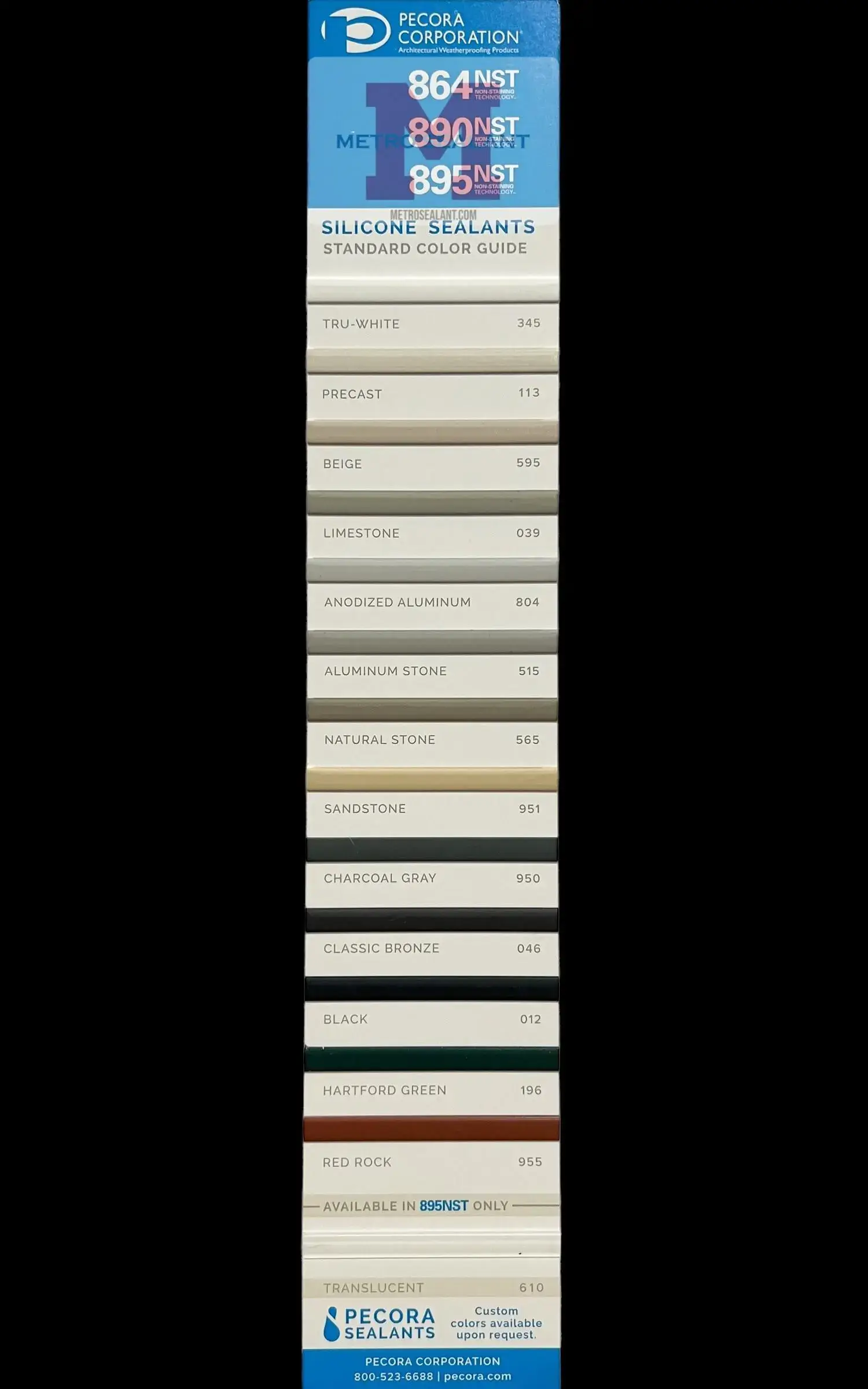

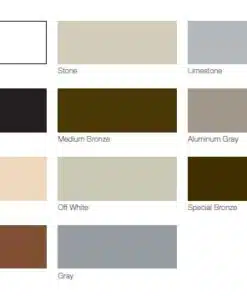

| Color | Aluminum Stone, Anodized Aluminum, Beige, Black, Charcoal Gray, Classic Bronze, Hartford Green, Limestone, Natural Stone, Precast, Red Rock, Sandstone, Tru White |

Related products

Multi component

All Products

All Products

Aluminum

Sealant Products

All Products