Buy Pecora Dynatred: Non-Sag 1.5gal Pail

$102.62

- Pecora Dynatred is a multi-component, non-sag, traffic grade polyurethane sealant 1.5 gal pail

- Dynatred® is a two-part,chemically-curing, cold-applied elastomeric sealant with the effectiveness of self leveling, traffic-grade sealants and the versatility of a non-sag material.

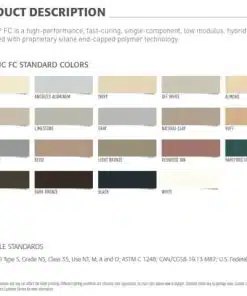

- Once full cure has been established (7 days),Dynatred® has exceptional resistance to water submersion. Its wide color range makes it an ideal sealant for decorative flooring, patios and pedestrian malls as well.

- For heavy pedestrian traffic areas subject to high heal exposure where joints exceed 3/8” in width, use Pecora Dynaflex.

138 in stock (can be backordered)