Blueskin VP160: Henry Vapor Permeable

$60.25 – $592.80

- Meets highest industry standards for commercial air barriers

- Sheds water while allowing vapor to pass through allowing walls to drain and substrates to dry

- Creates a continuous plane of air-tightness helping to improve building thermal performance

- Minimum Application Temperature: 20F (-7C)

- Fully adheres to substrates eliminating water migration

- Use Henry Crystal Clear 212 as a sealant at overlaps.

Blueskin VP160: Henry Vapor Permeable

Air-sealing your home is essential for creating a comfortable, safe, and efficient living space. If you are looking for a modern thermal performance solution to air sealing and water resistance in your building, our Blueskin VP160: Henry Vapor Permeable at Metro Sealant is the product you need.

About the Blueskin VP160: Henry Vapor Permeable

Blueskin VP160 is the latest innovation in air barrier technology and is making waves in the construction industry. Manufactured by Henry, it’s water-resistive air barrier and it consists of a rubberized asphalt compound. It offers superior protection against air infiltration and water penetration, helping to establish an energy-efficient building envelope with exceptional air tightness.

The Blueskin membrane offers excellent resistance to cold temperatures and ultraviolet radiation to help with durability during winter months or times of direct sun exposure. The product also features advanced film technology, which helps reduce noise transfer from outside sources. This makes Blueskin VP160 the perfect choice for residential or commercial buildings requiring acoustic insulation and superior weather protection.

Additionally, its easy installation requires no additional tools or equipment, saving time and money on labor costs.

Features:

- Water-Resistant: Offers robust protection against water penetration, preventing moisture-related issues.

- Flexible and Durable: Adaptable to various substrates and weather conditions, ensuring long-lasting performance.

- UV Resistant: Can withstand prolonged exposure to sunlight without degradation, maintaining its effectiveness over time.

- Suitable for Various Climates: Performs well in both hot and cold weather conditions, providing reliable protection all year round.

Finish your Henry System:

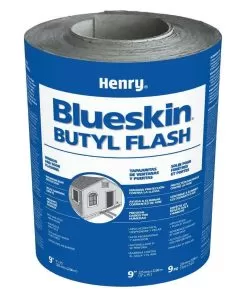

Henry Butyl Flash

To learn more about our Blueskin VP160: Henry Vapor Permeable, contact us today!

| Weight | N/A |

|---|---|

| Dimensions | 20.32 × 20.32 × 48 in |

| Size | 4" x 100', 6" x 100', 9" x 100', 12" x 100', 48" x 100' |

Related products

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier

Air and Vapor Barrier