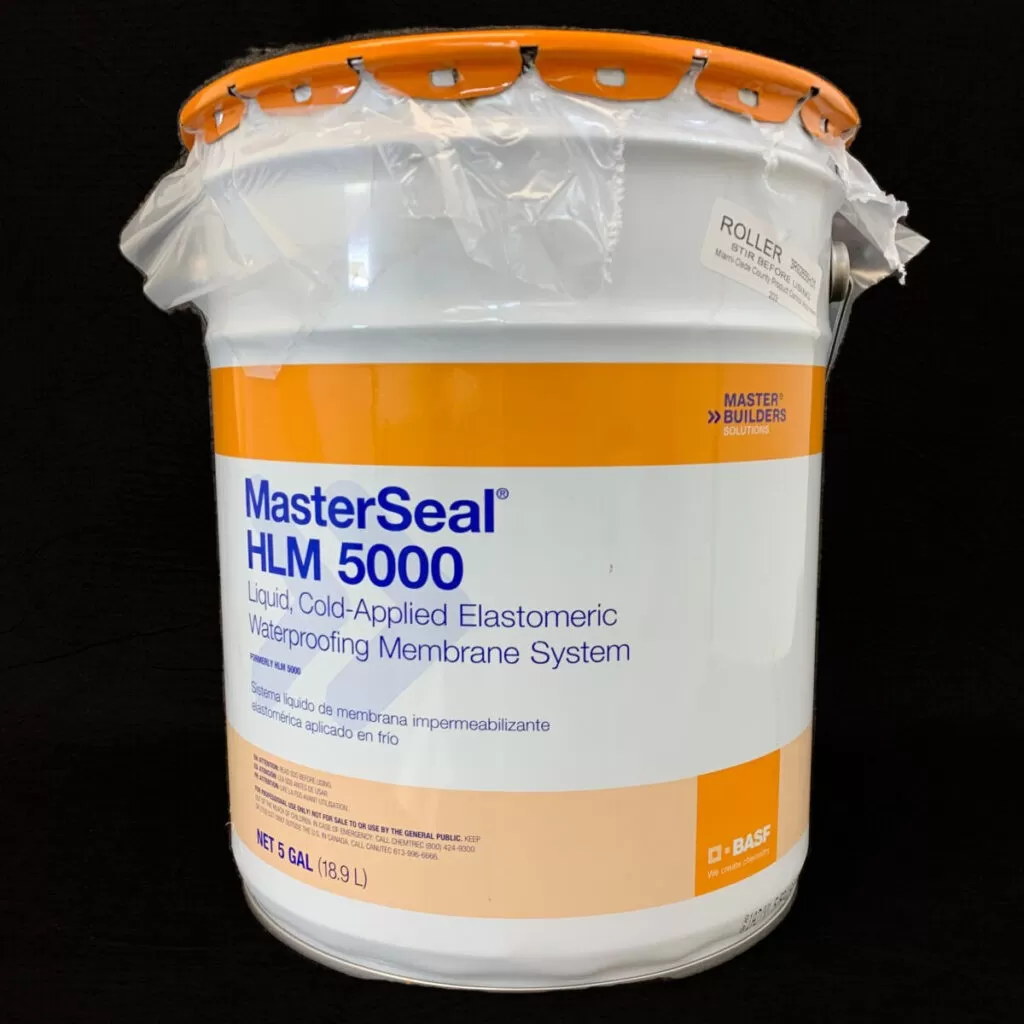

HLM 5000 Roller 5G: MasterSeal Membrane

$226.28

- Concrete

- Plywood (exterior)

- Exterior below grade (on masonry, concrete, and incidental metal)

- Above grade (between two-course concrete and within cavity walls)

- Parking garages and concrete tanks

- Plaza decks and malls

- Fountains and pools

- Balconies and planters

- Below-grade slabs

- Walls and culverts

- Sea walls, dams and reservoirs

- Waterproofing membrane to prevent water penetration

- Elastomeric accommodates expansion and contraction

- Wide service-temperature range, making MasterSeal HLM 5000 suitable for all climates

- Chemical resistance to bacterial attack, select acids, alkalis and salts

- Seamless cold-applied membrane eliminates lapping, seaming and precutting

21 in stock

HLM 5000 Roller 5G: MasterSeal Membrane

HLM 5000 Roller Masterseal: Liquid, Cold-Applied Elastomeric Waterproofing Membrane System:

How does it work?

MasterSeal HLM-5000 is a one-component, moisture-curing, bitumen-modified polyurethane elastomeric waterproofing membrane for exterior below-grade or between-slab applications. Questions? Contact Us

Recommended uses:

- Concrete

- Plywood (exterior)

- Exterior below grade (on masonry, concrete, and incidental metal)

- Above grade (between two-course concrete and within cavity walls)

- Parking garages and concrete tanks

- Plaza decks and malls

- Fountains and pools

- Balconies and planters

- Below-grade slabs

- Walls and culverts

- Sea walls, dams and reservoirs

APPLICATION

A test application is always recommended before proceeding with entire application. NOTE: Finish coat must be applied in a pinhole-free, continuous membrane for waterproofing integrity.

STANDARD SYSTEM

1.Select the grade of MasterSeal HLM 5000 that best meets individual job requirements. Use MasterSeal HLM 5000 T for trowel application, MasterSeal HLM 5000 S for spray application, MasterSeal HLM 5000 R for roller application or MasterSeal HLM 5000 SL for squeegee application.

2.For horizontal applications, empty contents of pail and spread immediately to ensure workability. Best results are obtained by marking off 125 ft2

(11.61 m2) areas and evenly spreading the contents of a 5 gallon (18.93 L) unit with a rubber-edged notched squeegee. Repeat the above procedure until the entire surface is covered.

3.For vertical applications, apply by trowel, roller or spray at the rate of 25 ft2/gallon (0.6 m2/L). Best results are obtained by marking off 125 ft2 (11.6 m2/L) and evenly applying the contents of a 5 gallon (18.93 L) pail.

4.Verify the applied thickness with a wet mil gauge as the work progresses.

5.The integrity of the cured membrane on a horizontal surface may be verified by damming the entire area and flooding with water to a minimum depth of 2″ (51 mm) and allowing the water to stand for 24–48 hours. Visually inspect the bottom surface to check for any water penetration. If repairs are necessary, the area should be drained

and allowed to dry before reapplying MasterSeal HLM 5000. After reapplication, the area should be tested again for membrane integrity.

What are the unique features?

- Available in standard and high-build systems

- Available in four grades:

- MasterSeal HLM-5000SL (self-leveling/squeegee)

- MasterSeal HLM-5000S (spray)

- MasterSeal HLM-5000T (trowel)

- MasterSeal HLM-5000R (roller)

What are the benefits of HLM 5000?

- Waterproofing membrane to prevent water penetration

- Elastomeric accommodates expansion and contraction

- Wide service-temperature range, making MasterSeal 5000 suitable for all climates

- Chemical resistance to bacterial attack, select acids, alkalis and salts

- Seamless cold-applied membrane eliminates lapping, seaming and precutting

Masterseal 5000

| Weight | 51 lbs |

|---|---|

| Dimensions | 15 × 15 × 18 in |

Related products

All Products

All Products

All Products

All Products

All Products

All Products

Customer Reviews