Sikaflex 1A: 10.1 fl. oz Tubes

$7.82

Sikaflex 1A is a premium-grade, high-performance, moisture-cured, 1-component, polyurethane-based, non-sag elastomeric sealant. Sikaflex 1A can be used in green and damp concrete applications. Meets Federal Specification TT-S-00230C, Type II, Class A. Meets ASTM C-920, Type S, Grade NS, Class 35, use T, NT, O, M, G, I, A. Canadian standard CAN/CGSB 19.13-M87.

Sikaflex 1A: 10.1 fl. oz Tubes

Are you looking for an elastomeric sealant that is high-performing, premium-grade, moisture curing, 1-component, polyurethane-based, and does not sag? Find out more about the features of the Sikaflex 1A: 10.1 fl. oz Tubes and order online from Metro Sealant.

About the Sikaflex 1A: 10.1 fl. oz Tubes

Sikaflex 1A: 10.1 fl. oz Tubes are perfect for joints where the maximum depth of sealant does not exceed ½ in. It is most suitable for horizontal and vertical joints and is easily placeable at 40°F. It saves the time and effort required for filling and mixing cartridges, thawing, or pre-heating, and cleaning the equipment.

It has excellent resistance to weathering and aging which has been proven in harsh weather conditions and climates around the world. It has no odor and leaves no stain. It can be painted with water, oil, and rubber-based paints.

Before application, make sure that the surface area on which the application is supposed to happen, is clean and dry, and free of any oil, grease, moisture, or any other foreign material. Use tool sealant to ensure full contact with joint walls and remove the air entrapped.

For removal, use personal protective equipment, and without any direct contact, remove the excess or waste product and place it in a container. Dispose of the container and there you go.

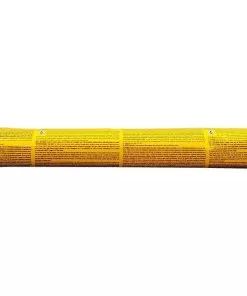

Sikaflex 1a also comes in 20oz sausages see here!

Why Buy Sikaflex 1A: 10.1 fl. oz Tubes from Metro Sealant?

At Metro Sealant, we try to help you get exactly what you need without having to go through the trouble of searching and surfing all over the internet. We offer a wide variety of the best and recommended solutions, just for you.

Finish your job with Sika:

See Technical Data Sheet for coverage rate.

To learn more about our Sikaflex 1A: 10.1 fl. oz Tubes, contact us today!

| Weight | 1 lbs |

|---|---|

| Dimensions | 12 × 2 × 2 in |

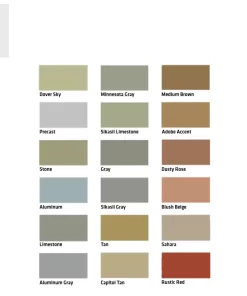

| Color | Aluminum Gray, Black, Capitol Tan, Colonial White, Dark Bronze, Limestone, Medium Bronze, Stone, White |

Related products

Color Pack/ Multi Component

Sealant Products

All Products

Adhesives

Sealer/Waterproofing