Sale!

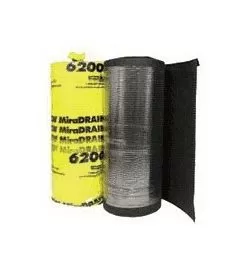

Hydroduct 220: 4’x 50′ Drainage Composite

Original price was: $272.12.$195.60Current price is: $195.60.

Hydroduct 220 is a strong, preformed 0.44 in. (11 mm) thick geocomposite drainage sheet system, comprising a hollow studded polypropylene core, covered on one side with a nonwoven, needle punched polypropylene filter fabric and on the other side with a smooth polymeric film. Primarily for use with waterproofing materials in vertical installations. Highly practical collector and deflector of unwanted ground water on foundation walls, retaining walls, tunnels and planters. Hydroduct 220 4’x50′ covers 200 ft2 a roll.

143 in stock